You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What gunsmithing or repairs have you done today

- Thread starter troy fairweather

- Start date

troy fairweather

Member

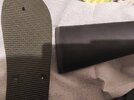

........and Jimmy Buffet is grinning in gunsmith heaven.Made a flip flop recoil pad today for the winchester,

entropy

Member

Got the the bench and there was a Plastic bag holding a LOADED Pietta 1851, the tag said "Does not turn" and that's it. After pulling the cylinder, I noticed the caps were sitting high on the nipples, so I popped them off with my knife blade, and put some #11s on. Turned fine. So I unloaded it (gotta test fire them), cleaned it, and put it back together with a note to the customer to use either #11 caps, or get caps that fit the nipples on the gun.

Not a gunsmith repair but rather a nice inventory upgrade; a small bench top vise for holding small micrometers in particular. I find mic-ing small parts requires a third hand hat trick sometimes. Now, I can just hold the part in one and dial the micrometer with the other....no drama.

Micro-Mark's new offering all steel / anodized aluminum vise with a heavy non-skid base, almost one pound. Has precision fixture-like pin holes to hold round or odd shaped work pieces. $55.

Micro-Mark's new offering all steel / anodized aluminum vise with a heavy non-skid base, almost one pound. Has precision fixture-like pin holes to hold round or odd shaped work pieces. $55.

What a useful tool!Not a gunsmith repair but rather a nice inventory upgrade; a small bench top vise for holding small micrometers in particular. I find mic-ing small parts requires a third hand hat trick sometimes. Now, I can just hold the part in one and dial the micrometer with the other....no drama.

Micro-Mark's new offering all steel / anodized aluminum vise with a heavy non-skid base, almost one pound. Has precision fixture-like pin holes to hold round or odd shaped work pieces. $55.

View attachment 1205655View attachment 1205656View attachment 1205657View attachment 1205658

45 Dragoon

Member

- Joined

- May 18, 2013

- Messages

- 2,784

The way I get around that is to remove the switch/speed control and wire in a Singer Sewing machine control pedal. That gives you a truly full range of speed control. I'm sure you know but my diamond rotary files last a very long time since i can run them extremely slow. I hang the motor up and utilize a flex shaft and of course if I need both hands free, I chuck the handle up in my small vice. I replaced my first Dremel about 6 or so years ago with the then new Model 4000 and it's still "zipping" right along!! It gets used for hours daily as it's my most used tool in the shop (still using the original brushes!!!).The problem with the Dremel power plant, even the cordless, is that several thousand rpm is the slowest speed!

So, just thought I'd share that with you. Enjoyed this thread for a long time! Thanks to Troy for starting it!!

Mike

NIGHTLORD40K

Member

Hows your locking block holding up? IIRC, that was a particular problem area on the Helwans.On Monday I chipped the extractor shooting my Helwan 9mm (Egyptian-made Beretta 1951). A quick visit to Jack First gun parts to order a $28.00 replacement, it was here by Wednesday.

View attachment 1201889

It took a bit of filing and finishing with 1000 grit wet-dry to get the new part to fit in the extractor groove in my slide.

View attachment 1201890

Once fitted, it fed-extracted my dummy rounds just fine. Hopefully I will escape to the range tomorrow to see how it functions with live ammo.

Stay safe.

AzShooter1

Member

Started out cleaning my 10/22, replaced the battery in my C-More Railway and loaded up 12 magazines so that I'm ready for tomorrow's Steel Challenge Match.

Mounted a new scope on my CZ 457 but I'm replacing it next week when my new scope comes from Natchez's. I've been shooting 6 X 18s but found a 4 X 24 with better turrets and better glass. Never heard of Veridian scopes before but I'm going to give it a try.

Mounted a new scope on my CZ 457 but I'm replacing it next week when my new scope comes from Natchez's. I've been shooting 6 X 18s but found a 4 X 24 with better turrets and better glass. Never heard of Veridian scopes before but I'm going to give it a try.

You set yours up like a Fordham rotary system.remove the switch/speed control and wire in a Singer Sewing machine control pedal.

45 Dragoon

Member

- Joined

- May 18, 2013

- Messages

- 2,784

Last edited:

troy fairweather

Member

Did another top coat of matte clear on my camo m70 stock.

Interesting demonstration of the how a small tap wrench is Not a precision instrument. You may want to consider avoid using the T-wrench for small taps to avoid breaking them off in the work.

Joe Pie video is well done.

https://www.youtube.com/watch?v=C0PBPGjd0Pc

I do use small Starrett tap wrench with a T-bar on the mill after drilling the hole. Perhaps not any more. I also

have fabricated the small cylinder thumb drive for small taps to avoid excessive torque the t-handles can impart on the taps, which then break!

Most spring-loaded tap guides are dual-ended, a radius-ed end and a tapered end to engage tap wrench or directly to the tap. The set screw on the tap guide is removable to switch ends of the guide and one can adjust the spring tension by extent of compressing the internal spring with the set screw.

I think knowledge about small details like this separate the pro's from the public at large.

.

.

Joe Pie video is well done.

https://www.youtube.com/watch?v=C0PBPGjd0Pc

I do use small Starrett tap wrench with a T-bar on the mill after drilling the hole. Perhaps not any more. I also

have fabricated the small cylinder thumb drive for small taps to avoid excessive torque the t-handles can impart on the taps, which then break!

Most spring-loaded tap guides are dual-ended, a radius-ed end and a tapered end to engage tap wrench or directly to the tap. The set screw on the tap guide is removable to switch ends of the guide and one can adjust the spring tension by extent of compressing the internal spring with the set screw.

I think knowledge about small details like this separate the pro's from the public at large.

.

.

Last edited:

Yesterday, making a lathe center gauge for aligning 60 deg tool bit for single point thread fabrication. I have the Browning & Sharpe

style that holds the gauge with a spring with the gauge slot. I wanted a more secure hold for the gauge so I used 4-40 set screws. Used a softer spring rate in spring-loaded tap guide with the 4-40 tap; don't want to be fighting a stiff axial load and lateral thread force at the same time on the small tap to avoid fracturing it in the hole.

A chance to use some other small gunsmith part fabrication tools as well.

Here's the journey.

style that holds the gauge with a spring with the gauge slot. I wanted a more secure hold for the gauge so I used 4-40 set screws. Used a softer spring rate in spring-loaded tap guide with the 4-40 tap; don't want to be fighting a stiff axial load and lateral thread force at the same time on the small tap to avoid fracturing it in the hole.

A chance to use some other small gunsmith part fabrication tools as well.

Here's the journey.

Last edited:

Armorer 101

Member

Attachments

This is a full-circle Sig P6 story. I acquired both a Sig P225 and its specialty variant the P6 in pristine form many years ago. The P6 was imported by Century Arms International ("C.A.I") in Georgia, Vermont of all places. C.A.I. was a subsidiary of Century International Arms ("C.I.A"), however, importing German arms with a C.I.A. inscription was asking for too much attention, so the company word-smithed the inscription to C.A.I.....that is what mine has emblazoned on the side.

The P6 was a specialty German "Polezei" request for improving and distinguishing the popular single stack P225:

1. Increase the double-action pull weight to 12 lbs, from 10 lbs.

2. Modify the barrel feed ramp to improve hollow-point ammo feeding, as it was becoming popular in early'90's.

3. A unique "notched" hammer profile, i.e. "deformation hammer" that German armorers would inspect to perceive if the pistol had been dropped and landed on its hammer. IF so, the armorer would replace the hammer, hammer strut and firing pin as their integrity could all have been negatively affected by such a direct impact on the hammer.

4. "P6" roll mark on the slide

The period German holsters for the P225 / P6 were common thumb strap affairs which could easily launch their pistol with just the wrong momentum vector. Thus, the tell-tale deformation hammer as described in the P6 Manual.

I just acquired a new-old-stock Sig factory sight pusher specifically for the P225 / P6 which was the impetus for this long-winded account. It seems well made, in particular it has graduations to discern the extent of sight movement.......dah......just what the MGW Pro sight pusher does not have which I fabricated some movement graduations on their sight pusher, with the precision of the mill. The factory sight tool also has two screws to impart tension to the pawl of the slide underside to stabilize it against forces during the process. The MGW pro sight has specific "shoes" that accomplish the same task in a more comprehensive manner.

Finally, legacy forum member RCModel had a thread on improving the P6 with a substitution of a P225 hammer spring, which I did

contemporaneously.

The P6 was a specialty German "Polezei" request for improving and distinguishing the popular single stack P225:

1. Increase the double-action pull weight to 12 lbs, from 10 lbs.

2. Modify the barrel feed ramp to improve hollow-point ammo feeding, as it was becoming popular in early'90's.

3. A unique "notched" hammer profile, i.e. "deformation hammer" that German armorers would inspect to perceive if the pistol had been dropped and landed on its hammer. IF so, the armorer would replace the hammer, hammer strut and firing pin as their integrity could all have been negatively affected by such a direct impact on the hammer.

4. "P6" roll mark on the slide

The period German holsters for the P225 / P6 were common thumb strap affairs which could easily launch their pistol with just the wrong momentum vector. Thus, the tell-tale deformation hammer as described in the P6 Manual.

I just acquired a new-old-stock Sig factory sight pusher specifically for the P225 / P6 which was the impetus for this long-winded account. It seems well made, in particular it has graduations to discern the extent of sight movement.......dah......just what the MGW Pro sight pusher does not have which I fabricated some movement graduations on their sight pusher, with the precision of the mill. The factory sight tool also has two screws to impart tension to the pawl of the slide underside to stabilize it against forces during the process. The MGW pro sight has specific "shoes" that accomplish the same task in a more comprehensive manner.

Finally, legacy forum member RCModel had a thread on improving the P6 with a substitution of a P225 hammer spring, which I did

contemporaneously.

Attachments

Last edited: