I built this pusher for the last of the small primers:got a new issue I haven't read about. I just ordered the "large" case slider for the old style Pro1000 case feeder. The "universal" one they sell now is different, and everyone was out of stock of the large case slider old style except Midway. Anyhow, it works fine until the last case or two, (.45 ACP) but those slide down the little ramp on the top of the slider and momentum carries them too far forward on the carrier and the case blocks the upward stroke of the ram unless I push it back against the slider. Not a huge deal, and the setup is definitely waaay faster than placing a piece of brass onto the slider/carrier by hand (which I have been doing for the past few days while I waited for the large case slider) but I wondered if anyone had experienced this issue and had a fix.

BTW the large/tall slider fixes the other issue with using the 9mm-sized slider on tall .45 cases, where the pressure of the stack of cases above it would cause the bottom one to tip as the slider pushed it forward. I assume that's why there are two sizes of sliders.

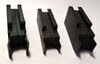

Also, my large primers are feeding without issue which is awesome. As long as I remember to refill the primer tray before the stack of primers gets below halfway on the trough, I have zero issues. I wonder if the LPP are heavier and slide better. My small primer carrier is more finicky even after the "burnishing" and custom cover fixes suggested.

https://www.thehighroad.org/index.p...utions-no-bashing.507454/page-7#post-10488122

works for me, no more shaking/tapping,