I saw a fellow trying something like that at a BR match a long time ago. I have no idea if it worked or if he kept using it or not.using Lock Eze fluid on a patch as their last step

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My 2 cents on bore cleaning (with more Teslong pics)

- Thread starter Nature Boy

- Start date

- Status

-

Not open for further replies.

Nature Boy

Member

- Joined

- Apr 21, 2015

- Messages

- 8,228

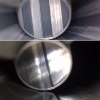

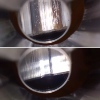

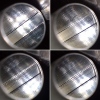

My kids and I shot an F class match last weekend. My daughter shot a .308 with Bartlein 5R barrel that has 3,300 rounds through it. I started cleaning it first and thought I’d share the before and after pics. Approximately 75 rounds fired.

1. Area near the breach. You can see the fire cracking in this area

2. Midway down

3. At the muzzle

1. Area near the breach. You can see the fire cracking in this area

2. Midway down

3. At the muzzle

I got my Teslong today. Only had time to look at one of my rifles, an AR that I knew was not perfect, but thought it was much better that it was. The scope is awesome, what I am seeing not so sure .

A nice tool to have in your box though.

Jeff

A nice tool to have in your box though.

Jeff

Last edited:

I am also a fan of removing powder fouling and deep cleaning every 2 to 300 rounds. I am a Butches bore shine guy, and will use the felt pellets with bore paste and kroil when the fouling is bad. Also if you haven't tried it I have had some success coating my bullets with Tungsten disulfide and can stretch out deep cleanings to 400 rounds. The heavier projectiles do best with the coating in 30 cal and 6mm. You know the saying ..."an ounce of prevention."

Butches, or Tungsten disulfide?Will never put that stuff in a bore again. YMMV

d2wing

Member

- Joined

- Nov 10, 2008

- Messages

- 6,404

I finally got the Wipe out . I used the accelerator first then sprayed the Wipeout down the barrel and left it for a couple hours. Then I ran a couple patches that came out blue and dirty, a third was pretty clean. One more and I looked down the bore with the scope and I was amazed how clean it was. The copper deposits were gone and the barrel was clean. The battery went dead before I could get a picture but I am very impressed. I am sold on Wipeout.

bfoosh006

Member

- Joined

- Jan 29, 2008

- Messages

- 1,083

The two out of the group the first clean bore shots?

Sorry, the Devil made me do it.

Great shooting.

No... Lol... My self inflicted, don't flub the last shot... from my over active mind.

Nature Boy

Member

- Joined

- Apr 21, 2015

- Messages

- 8,228

No... Lol... My self inflicted, don't flub the last shot... from my over active mind.

It can get worse. Shoot an F Class match where you have all your shots for record inside the 10 ring and you get down to the last 20, then the last 10, then the last 5 and that 10 ring shrinks up in direct proportion to your sphincter

I use KG 12 and a nylon brush. Gets rid of copper easily without the worry of ammonia based cleaners remaining in the barrel too long. Leave KG 12 in the barrel for about two minutes, scrub with nylon brush a few times(5 or 6 passes) run a few patched thru to clean out the gwadoo and instant shiny barrel....easy peasy. Follow with a bit of oil on a patch for ultra shine and protect against future rust.

Nature Boy

Member

- Joined

- Apr 21, 2015

- Messages

- 8,228

The Tubb fire lapping bullets came in yesterday. I just finished loading them up and will shoot them tomorrow. I hope to accomplish a few things.

1. I’ll shoot 5 shots with my current hunting load with a coating of Lock Eze in the barrel to see how it affects the first clean cold bore shot. This will also give me a base line on group size before the fire lapping begins

2. Shoot the Tubb final finish fire lapping system. I’ll take pictures of the bore between stages to see how it changes.

3. Shoot 5 shots with my hunting load to see if fouling and accuracy are improved

1. I’ll shoot 5 shots with my current hunting load with a coating of Lock Eze in the barrel to see how it affects the first clean cold bore shot. This will also give me a base line on group size before the fire lapping begins

2. Shoot the Tubb final finish fire lapping system. I’ll take pictures of the bore between stages to see how it changes.

3. Shoot 5 shots with my hunting load to see if fouling and accuracy are improved

Use. KG 1 on carbon...same result, very easy. I use it first and copper remover KG 12 secondHow does it do on carbon?

Nature Boy

Member

- Joined

- Apr 21, 2015

- Messages

- 8,228

Looking forward to your results. If you have time and inclination, would be interesting to see if/how much drop in velocity occurs after TFF.

Regards,

hps

yep, I’ll do that too

d2wing

Member

- Joined

- Nov 10, 2008

- Messages

- 6,404

I didn't see any left in the barrel. Wipe out must remove that also.How does it do on carbon?

Nature Boy

Member

- Joined

- Apr 21, 2015

- Messages

- 8,228

I didn't see any left in the barrel. Wipe out must remove that also.

It will get the powder fouling but the hard carbon requires some mechanical action to remove, a good bronze brush or some bore paste

243winxb

Member

More photos here. http://forum.accurateshooter.com/threads/help-me-determine-what-this-is-bore-photo.3996900/

Teslong borescope.

I am afraid to look at my 1970s barrels.

at my 1970s barrels.

Teslong borescope.

I am afraid to look

Nature Boy

Member

- Joined

- Apr 21, 2015

- Messages

- 8,228

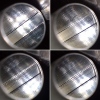

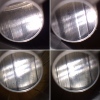

Shot the Tubb Final Finish fire lapping system on Sunday and here’s the results

The system comes in 5 groups, 10 bullets each, from most aggressive to least aggressive.

I loaded them per instructions with a starting load 42g of H4895

Headed to the range, shot a base line 3 shot group with my hunting load, then proceeded to follow the steps of shooting the most aggressive 10 round group, clean throughly, then shoot the next, clean, and repeat until all 50 are fired

After completing the process I cleaned the barrel and shot a 3 shot comparison group with my hunting loads. Before on the top, after on the bottom

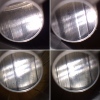

I also chronographed these shots, 2,300 fps before and 2,290 after. Interesting how the holes are ragged before and clean after.

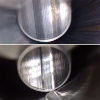

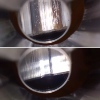

Finally, here’s how the bore looked before. Note how the radial tool marks transition the lands and grooves

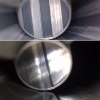

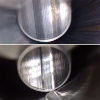

Here’s the after. Tool marks on the lands are completely gone and the center of the grooves have been improved. The top left pic shows the throat. It doesn’t seem to have been moved very much

My conclusion is this Tubb system did have a positive effect on this barrel. It definitely coppers less and was easier to clean. Might have improved accuracy but I’ll need to shoot more to know that for sure.

It takes some time and a bit of effort to perform this process. I would not use this on any of my custom barrels but if you had a rough commercial barrel that was fouling a lot, had related accuracy issues, I don’t think you’d be hurting anything if you gave it a try

The system comes in 5 groups, 10 bullets each, from most aggressive to least aggressive.

I loaded them per instructions with a starting load 42g of H4895

Headed to the range, shot a base line 3 shot group with my hunting load, then proceeded to follow the steps of shooting the most aggressive 10 round group, clean throughly, then shoot the next, clean, and repeat until all 50 are fired

After completing the process I cleaned the barrel and shot a 3 shot comparison group with my hunting loads. Before on the top, after on the bottom

I also chronographed these shots, 2,300 fps before and 2,290 after. Interesting how the holes are ragged before and clean after.

Finally, here’s how the bore looked before. Note how the radial tool marks transition the lands and grooves

Here’s the after. Tool marks on the lands are completely gone and the center of the grooves have been improved. The top left pic shows the throat. It doesn’t seem to have been moved very much

My conclusion is this Tubb system did have a positive effect on this barrel. It definitely coppers less and was easier to clean. Might have improved accuracy but I’ll need to shoot more to know that for sure.

It takes some time and a bit of effort to perform this process. I would not use this on any of my custom barrels but if you had a rough commercial barrel that was fouling a lot, had related accuracy issues, I don’t think you’d be hurting anything if you gave it a try

Last edited:

- Status

-

Not open for further replies.

Similar threads

- Replies

- 15

- Views

- 850

- Replies

- 1

- Views

- 331