You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Results of gun care product evaluation

- Thread starter DIY_guy

- Start date

Skylerbone

Member

DIY, any chance you'd save up a bit of oil and fingerprint the top 3 from boards #1 & #2 on the inside board #3? The indefinite average storage conditions test is solid but for the thought that people may inadvertantly touch the metal after cleaning. If you didn't care to disturb the 3rd panel, perhaps a fresh set of 3 steel plates to see who comes out on top? I know, spending your money is easy...thank you again for the updates.

Rather than posting the day of the failure on the thumbprint portion of the indoor plates I have waited to lump the recent failures into a single post. Here they are. Again this is only in the thumb print area of the plate.

As for the outdoor boards. Board #2 has now had every product show corrosion at 29 days. Board #1 is at 30 days with the same remaining products still fighting off corrosion.

As for the outdoor boards. Board #2 has now had every product show corrosion at 29 days. Board #1 is at 30 days with the same remaining products still fighting off corrosion.

ohbythebay

Member

DIY_Guy...

You are an OCD genius...hats off to you...your friction rig is pretty freakin awesome...

Definitely gets my vote for post of the year...

You are an OCD genius...hats off to you...your friction rig is pretty freakin awesome...

Definitely gets my vote for post of the year...

ohbythebay

Member

DIY_Guy...anu updates?

Are the boards still in the wind or is it a wrap? Just curious...

Are the boards still in the wind or is it a wrap? Just curious...

Here is an update on the corrosion boards after 43 and 42 days outside.

The last three samples on board #1 are about to give up.

Board #2 samples are all finished. Every sample is showing corrosion.

The indoor samples (after 41 days) are showing more failures. (Only in the thumb print area)

Rust prevent, WD 40 regular), Militech1, Strike hold, Archoil, 3 In One iol, Kroil, Hoppe's MDL. Mil Poro 7 have now failed along with the others that had failed earlier.

The last three samples on board #1 are about to give up.

Board #2 samples are all finished. Every sample is showing corrosion.

The indoor samples (after 41 days) are showing more failures. (Only in the thumb print area)

Rust prevent, WD 40 regular), Militech1, Strike hold, Archoil, 3 In One iol, Kroil, Hoppe's MDL. Mil Poro 7 have now failed along with the others that had failed earlier.

Last edited by a moderator:

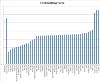

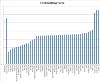

As mentioned earlier I put together a device to capture the dynamic coefficient of friction for all the products I have previously evaluated (including a static friction evaluation)

Ive tabulated the results and they are similar to those of the static coefficient of friction evaluation.

Here is a video showing how the evaluation was conducted and how excess lube actually worsens or confounds our attempts to make metal slide easier against one another. The video will show that only in the absolute minimalist state do the gun lubes actually reduce the friction/drag forces.

https://www.youtube.com/watch?v=J5LeeIfvLm0

All the products were run through the friction device and the chart below shows how each product performed in comparison to one another as well as dry steel (no lube at all)

Ive tabulated the results and they are similar to those of the static coefficient of friction evaluation.

Here is a video showing how the evaluation was conducted and how excess lube actually worsens or confounds our attempts to make metal slide easier against one another. The video will show that only in the absolute minimalist state do the gun lubes actually reduce the friction/drag forces.

https://www.youtube.com/watch?v=J5LeeIfvLm0

All the products were run through the friction device and the chart below shows how each product performed in comparison to one another as well as dry steel (no lube at all)

ohbythebay

Member

You are amazing...

This is excellent work. You have also achieved several unique results. The first is which lubes have the lowest drag coefficient. The second, and quite important, is that the lube should be wiped down to present the thinnest film.

Thank you !

P.S - I am still glad I went with Frog Lube...

This is excellent work. You have also achieved several unique results. The first is which lubes have the lowest drag coefficient. The second, and quite important, is that the lube should be wiped down to present the thinnest film.

Thank you !

P.S - I am still glad I went with Frog Lube...

krimmie

Member

Seems you get a lot for your money with WD-40 Specialist.

After 62 days the outdoor evaluation has concluded. This past June was one of the rainiest on record. I did not post the failure date of the last three products on the date of the failure so I could lump them together. Here are the final products to show corrosion.

Frog Lube after 54 days

Hornady One Shot after 58 days and

WD 40 Specialist at 62 days.

The indoor evaluation is still on-going.

Frog Lube after 54 days

Hornady One Shot after 58 days and

WD 40 Specialist at 62 days.

The indoor evaluation is still on-going.

Regarding the WD-40 Specialist, I was just about to put some in my Amazon cart last night while I was shopping for some cleaning brushes, until I decided to read some of the reviews. Several of them cited that it eventually turns tacky. Not sure how long it took for that to happen, but I was curious if the same has happened to the sample pieces in this test?

ETA: I ended up going with two different kinds of the Hornady One Shot. I really wanted to try the Frog Lube, but it just seemed too expensive to me.

ETA: I ended up going with two different kinds of the Hornady One Shot. I really wanted to try the Frog Lube, but it just seemed too expensive to me.

Doc7

Member

Thanks for this - I am now using One Shot. I have also used it to great effect on squeaky hinges and drawer slides.

Similar threads

- Replies

- 10

- Views

- 1K

- Replies

- 17

- Views

- 2K

- Replies

- 77

- Views

- 11K

- Replies

- 4

- Views

- 776