Load Master

Member

NOTE: This is just for information and in no way is it a suggestion for use.

Communication with Sellier & Bellot has been slow due to Holidays and vacations this time of year. A few weeks back I supplied S&B with details of my load data, measurements and photos. Their conclusion, if I were using their 5,3 LR-SE primer I would not have pierced primers at the load levels shown at the high end of my load development.

According to Sellier & Bellot ammunition development engineer, they produce a .308 Winchester “Snipper” round with higher velocity and pressure using the same projectile as compared to my loads. This round uses their 5,3 LR-SE primer. The 5,3 LR-SE is designed to stand up to the higher pressure loads. This is why they recommend it for .308 Winchester and other high pressure rounds. The problem for us here in the states, the 5,3 LR-SE isn’t currently offered. The folks I’ve been in communications with are looking into this and what it would take to offer them here. I expect this will take a fair amount of time if they ever become available in the US.

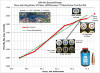

I do not plan to run anywhere near the load shown on the right of the attached chart. My best groups came in about 1/3 up from the left. Regardless, I would still like to be using S&B’s 5,3 LR-SE primers.

Communication with Sellier & Bellot has been slow due to Holidays and vacations this time of year. A few weeks back I supplied S&B with details of my load data, measurements and photos. Their conclusion, if I were using their 5,3 LR-SE primer I would not have pierced primers at the load levels shown at the high end of my load development.

According to Sellier & Bellot ammunition development engineer, they produce a .308 Winchester “Snipper” round with higher velocity and pressure using the same projectile as compared to my loads. This round uses their 5,3 LR-SE primer. The 5,3 LR-SE is designed to stand up to the higher pressure loads. This is why they recommend it for .308 Winchester and other high pressure rounds. The problem for us here in the states, the 5,3 LR-SE isn’t currently offered. The folks I’ve been in communications with are looking into this and what it would take to offer them here. I expect this will take a fair amount of time if they ever become available in the US.

I do not plan to run anywhere near the load shown on the right of the attached chart. My best groups came in about 1/3 up from the left. Regardless, I would still like to be using S&B’s 5,3 LR-SE primers.