SpentCasing said:

So the OAL in the book is a lowest point?

No. The OAL in the book is the OAL that was used to test the average maximum chamber pressures for that load data.

I can safely go higher than suggested OAL but never lower, correct?

Not quite, The listed OALs in published load data are not "suggested" OALs but simply OALs that were used for the test barrel fixtures (and not real pistols) to measure average maximum chamber pressures. Different pistols/barrels may require shorter/longer than listed OALs to reliably feed and fully chamber the finished rounds.

G17 bbl, My max COAL is longer than SAAMI spec. (1.169)

So does that mean that this particular bullet (124gr XTP) is safe from SAAMI max spec all the way down to what Hornady states in thier book (1.060) in my bbl?

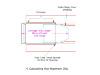

Not practically. Glock barrels have longer leade (see pictures below) and more gradual start of rifling than many barrels and will allow longer than SAAMI max OAL. Even though longer than SAAMI max OAL may pass the barrel drop test, it does not mean the round will fit the magazine and/or feed/chamber from the magazine when the slide is released. I usually start with SAAMI max OAL when I conduct my barrel drop test outlined in this thread.

Glock barrel

I want to go by the book, but the book lists really small OAL it seems especially compared to other books I have.

For semi-auto pistols, using book OAL WILL NOT ensure the listed OAL will reliably work with your pistols/barrels/magazines. For any new bullet you reload for your pistol, you should conduct the barrel drop test to determine the max OAL and function test to determine the working OAL.

This OAL stuff is really confusing me.

How about some easier step-by-steps?

Note: For the barrel drop and the function tests, I use .021" added to the bullet diameter for the taper crimp. So for .355" diameter bullet, I use .376" taper crimp.

Determine the max OAL:

- Remove the barrel from the pistol and clean the barrel, including the chamber

- Using a dummy round (no powder/no primer), start with the SAAMI max OAL and incrementally decrease the OAL until the dummy round falls in the chamber freely with a "plonk" and spin without hitting the start of rifling

- This OAL is your max OAL

Determine the working OAL:

- Put the barrel back in the slide and reassemble the pistol

- Lock the slide back

- Load the max OAL dummy round in the magazine and insert in the pistol

- Release the slide without riding the slide

- If the dummy round won't fully chamber reliably, incrementally decrease the OAL until it does

- This OAL is your working OAL

Conduct powder work up:

- Reference all available published load data from powder and bullet manufacturers for the given bullet weight and nose type and establish the lowest start-to-max powder charges

- If the working OAL is longer than published OAL and the bullet seating depth is shallower, use the published start/max charges

- If the working OAL is shorter than published OAL and the bullet seating depth is deeper, consider decreasing the start/max charges by .2/.3 grain.

- Load 5-10 rounds of .1-.2 incremental charges from start-to-max charges using the working OAL

- Range test to determine the powder charge that starts to reliably cycle the slide, fully feed/chamber rounds from the magazine and reliably extract the spent cases (depending on the bullet/powder combination, this may happen either at start-to-mid range load data or mid-to-high range load data)

- Continue the range test while monitoring the accuracy trend. The powder charge that begins to produce accurate shot groups is your lighter recoil/range practice/plinking/target load (depending on bullet/powder combination, this may happen either at mid-to-high range load data or high-to-near max load data)

mid-range target load vs full-power max load:

- Some powders with faster burn rate than W231/HP-38/Unique/Universal will start to produce accuracy even at mid-range load data at slower velocities. I use these powders for slower velocity target loads.

- Some powders with slower burn rate than W231/HP-38/Unique/Universal will produce optimal accuracy at high-to-near max load data. I will use these powders for higher velocity full-power loads.

Using mixed range pick up brass and max loads:

If you use mixed range pick up brass to reload, you may want to consider this, especially if you have barrels with less than fully supported chambers.

The spent cases you pick up at the range or purchase may have been reloaded several times and you do not know the condition of the brass strength, mealiability, etc. For these reasons, I reserve known once-fired rounds I saw go from factory boxes to the pistols for max loads to shoot in 40S&W Glocks. For me, I use mid-to-high range load data for mixed range brass with unknown reload history. I may be too cautious doing this but have not experienced any KaBoom in my 9mm/40S&W/45ACP Gen2/Gen3 Glocks with factory barrels the past 18 years even with using faster burning powders like Bullseye/Titegroup/Clays/Promo/Green Dot/WST/N320/W231/HP-38. YMMV

I hope this helped.