You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Media information

- Album

- Casting Bullets

- Added by

- 243winxb

- Date added

- View count

- 353

- Comment count

- 1

- Rating

- 0.00 star(s) 0 ratings

Caption

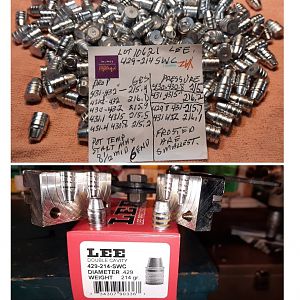

Problem alloys. How to clean.

When things are not right after fluxing and casting, shut the pot down. Let the alloy fully cool.

Next, bring the pot temperature up VERY SLOWLY. Just till the alloy becomes liquid. No fluxing, or mixing allowed.

The oatmeal needs carefully skimmed from the surface and trashed.

Now turn heat up to maximum in Lee pot. Flux with 50/50 bees wax/alox. Vapor should catch fire. Clean dross off.

Start casting till bullets show frost, drop pot temperature a little. Allow mold to cool a little.

This has removed a high percentage of copper, that keeps pluging the bottom pour spout. (Babbitt alloy)

When things are not right after fluxing and casting, shut the pot down. Let the alloy fully cool.

Next, bring the pot temperature up VERY SLOWLY. Just till the alloy becomes liquid. No fluxing, or mixing allowed.

The oatmeal needs carefully skimmed from the surface and trashed.

Now turn heat up to maximum in Lee pot. Flux with 50/50 bees wax/alox. Vapor should catch fire. Clean dross off.

Start casting till bullets show frost, drop pot temperature a little. Allow mold to cool a little.

This has removed a high percentage of copper, that keeps pluging the bottom pour spout. (Babbitt alloy)

Image metadata

- Filename

- Lee Molds.jpg Edit.jpg

- File size

- 345.5 KB

- Dimensions

- 1032px x 1451px