Although acetylene has a higher flame temperature (3160 °C, 5720 °F), MAPP has the advantage that it requires neither dilution nor special container fillers during transport, allowing a greater volume of fuel gas to be transported at the same given weight, and it is much safer in use.

MAPP gas has not been mfg. in North American since 2008

MAPP gas was a trademarked name, belonging to The Linde Group, a division of the former global chemical giant Union Carbide, for a fuel gas based on a stabilized mixture of methylacetylene (propyne), propadiene and propane. The name comes from the original chemical composition,

Methyl

Acetylen

e (48%)

-Propadiene (23%)

-Propane (27%).

MAPP is NOT Mapp Pro.

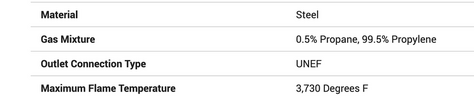

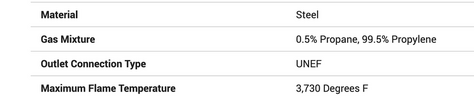

What is available is Mapp Pro= 0.5 % propaPe + 99.5 % propylene

Mapp Pro has propylene added that allows the gasses to transfer heat into the material faster, not hotter.

However, the original MAPP mfg. still use the same familiar yellow bottles for MAPP-Pro …..who knew.