unspellable

Member

Long enough the ends don't complicate the picture. If it's short enough the simple hoop strength formula doesn't apply. No idea what you are dealing with. A revolver cylinder is NOT a simple hoop case.What about short pipes. One of the biggest messes I had to rebuild concerned two very short pipes.

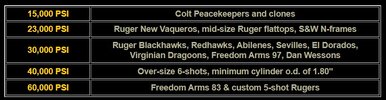

I've never seen one fail at the notch. I'm not saying it never happens, it's an uncontrolled event. But the usual failure is at the web. Get a copy of Julian Hatcher's "Textbook of Pistols and Revolvers", page 218 in my soft cover edition. where Colt lays this to rest. S&W did a similar experiment in more recent times. (BTW: Of several blown cylinders I've seen, the most idiotic was a S&W Model 10 with a full case load load of Bullseye.)Post a pic. I don't think so. Every cylinder I've seen ripped at the bolt notch. This is never in question.

I have two Taurus Raging Bulls, one in 454, the other in 45 Colt, 5 and 6 holes respectively. Same outer wall thickness in both, but thicker web in the 454.