twofewscrews

Member

As a winter project I decided to accurize my 10/22 without spending an arm and a leg. My goal is to get it to consistently shoot 1/2" groups or better at 50 yards. I properly free floated the barrel (Hogue Overmold stock), stiffened the stock (jb weld), added some weight (fishing sinkers), polished the bolt and receiver (scotchbrite and sandpaper), lightened the trigger via Volquartsen (most expensive part), and rubber bedded the first 2" of the barrel (permatex). The screw an Allen head screw, not a phillps head screw. I'm considering adding a pillar and possibly, but most likely not, having the bolt professionally worked on.

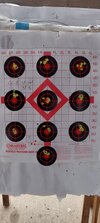

It went from shooting 1" to 3" groups to shooting 1/2" to 1" groups at 50 yards using CCI Standard Velocity. While CCI Standard Velocity is great for the cost, I need more consistent ammo to reach 1/2" groups or better. I bought some Eley Target, Club, Team, and Match ammo.

I've been reading conflicting information regarding "tuning" a 10/22 by adjusting the torque on the takedown screw. Supposidly you get better/worse groups by adjusting the torque setting. Some people swear by it and others call it voodoo. I've read that it makes a difference on woods stocks and not on synthetic stocks. I've read that it won't make a difference on a pillar bedded stock, and that it will only make a difference on a pillar bedded stock. I've read that it only makes a difference if there is play between the reciever and stock. For every claim that it works I've found another claim saying otherwise.

I did a test today that was inconclusive at best, however, I was not using the best ammo. I ran 165 rounds or so of the bulk Federal 36g CPHP through the gun using 15 to 30 in lbs of torque (1 in lbs at a time). I shot 3 groups at each setting, 5 shots in each group. There was no noticable difference. Its possible if I used better ammo (more consistent in velocity, weight, etc) I would have seen a difference, but I'm not sure.

What I did find was, that as far as I can tell, 15 in lbs, 20 in lbs, and 25 in lbs rotated the takedown screw head. 16-19 in lbs and 21-24 in lbs did not rotate the takedown screw head at all. This would suggest that 15, 20, and 25 in lbs are actually creating different levels of stress/pressure between the reviever/barrel and the stock, and the other torque values did nothing. I might grab a box or two of CCI St. Vel. and try this test again next week, but I'd rather not waste what little range time I have each week on something that doesn't really seem to make a difference.

For those of you with a 10/22, what have you expierenced?

Does the amount of torque you use make a difference to your group size?

If so, what is your setup? wood vs synthetic stock, pillar or no pillar, etc

It went from shooting 1" to 3" groups to shooting 1/2" to 1" groups at 50 yards using CCI Standard Velocity. While CCI Standard Velocity is great for the cost, I need more consistent ammo to reach 1/2" groups or better. I bought some Eley Target, Club, Team, and Match ammo.

I've been reading conflicting information regarding "tuning" a 10/22 by adjusting the torque on the takedown screw. Supposidly you get better/worse groups by adjusting the torque setting. Some people swear by it and others call it voodoo. I've read that it makes a difference on woods stocks and not on synthetic stocks. I've read that it won't make a difference on a pillar bedded stock, and that it will only make a difference on a pillar bedded stock. I've read that it only makes a difference if there is play between the reciever and stock. For every claim that it works I've found another claim saying otherwise.

I did a test today that was inconclusive at best, however, I was not using the best ammo. I ran 165 rounds or so of the bulk Federal 36g CPHP through the gun using 15 to 30 in lbs of torque (1 in lbs at a time). I shot 3 groups at each setting, 5 shots in each group. There was no noticable difference. Its possible if I used better ammo (more consistent in velocity, weight, etc) I would have seen a difference, but I'm not sure.

What I did find was, that as far as I can tell, 15 in lbs, 20 in lbs, and 25 in lbs rotated the takedown screw head. 16-19 in lbs and 21-24 in lbs did not rotate the takedown screw head at all. This would suggest that 15, 20, and 25 in lbs are actually creating different levels of stress/pressure between the reviever/barrel and the stock, and the other torque values did nothing. I might grab a box or two of CCI St. Vel. and try this test again next week, but I'd rather not waste what little range time I have each week on something that doesn't really seem to make a difference.

For those of you with a 10/22, what have you expierenced?

Does the amount of torque you use make a difference to your group size?

If so, what is your setup? wood vs synthetic stock, pillar or no pillar, etc

Last edited: