My father-in-law gave me a 25-06 Remington 700 before he died. Along with the rifle I got around 400 rounds of spent cases (various mfgs) from him. In a previous post, I mentioned that some of these rounds, after sizing them, jam in the chamber to the point where I have to tap the bolt handle backward with a rubber mallet to extract the round.

Some folks here mentioned that I may need to push the shoulder back. After trying that, with no luck - they still stuck in the chamber - I decided to check all several hundred sized cases to separate the ones that stuck. Only about 100 cases chambered successfully, all the others stuck.

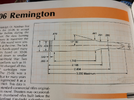

I compared measurements between the good and bad cases, as much as I can with a standard micrometer, and the only noticeable, and repeatable, difference is the diameter measurement near the base of the case. See the chart showing .470.

All the bad cases measure .468 or greater.

All the good case measure .466 or less.

Now my father-in-law had another 25-06 rifle that he used for many years along with the one he gave me. I'm wondering if the empty cases he gave me were used in both rifles, and the ones that are jamming in my rifle were actually shot in his other rifle.

Some questions:

1. Is .002 difference enough to cause these cases to get stuck in the chamber?

2. Could the chamber in the two rifles be just different enough to be a concern?

3. Will using a small-base sizing die on the cases that jam squeeze the base diameter down enough to make a difference here?

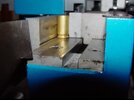

The other image shows two cases. The left one jams in the chamber and measures .468 at the base, the right one chambers slick and smooth and measures .466.

Thanks!

Some folks here mentioned that I may need to push the shoulder back. After trying that, with no luck - they still stuck in the chamber - I decided to check all several hundred sized cases to separate the ones that stuck. Only about 100 cases chambered successfully, all the others stuck.

I compared measurements between the good and bad cases, as much as I can with a standard micrometer, and the only noticeable, and repeatable, difference is the diameter measurement near the base of the case. See the chart showing .470.

All the bad cases measure .468 or greater.

All the good case measure .466 or less.

Now my father-in-law had another 25-06 rifle that he used for many years along with the one he gave me. I'm wondering if the empty cases he gave me were used in both rifles, and the ones that are jamming in my rifle were actually shot in his other rifle.

Some questions:

1. Is .002 difference enough to cause these cases to get stuck in the chamber?

2. Could the chamber in the two rifles be just different enough to be a concern?

3. Will using a small-base sizing die on the cases that jam squeeze the base diameter down enough to make a difference here?

The other image shows two cases. The left one jams in the chamber and measures .468 at the base, the right one chambers slick and smooth and measures .466.

Thanks!

Attachments

Last edited: