Mr.Revolverguy

Member

- Joined

- Feb 24, 2007

- Messages

- 1,882

Many before me have discussed 38 special wadcutter it’s accuracy and it’s ability to be a crusher. Ed Harris documented the effects of the DEWC (full wadcutter) in 38 special very well for us to reflect upon all of it’s goodness.

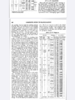

This got me to thinking if it was this good and still yet very capable today would it not be better in 357 Magnum? Only one problem stood in my way. I could not find one manufacturer producing 357 Magnum Full Wadcutter today. With the popularity of this round surely there would be loads documented some where for the reloading addict like myself. Google enters here, sure there are a lot of people talking about it but nothing well documented. As a matter of fact some of the loads that was documented is downright scary. I searched hi and low and nothing I would trust, most amazing I could not find any type of load even in reloading manuals dating back to the 80’s. This lack of data inspired me and started me on this journey to create Mr.Revolverguy’s 357 Magnum Bone Crusher.

Being a user of Quickload Ballistics for 5 years or more now and with about 4 loading manuals sprawled across my desk I knew I had all the right tools to be successful in my mission.

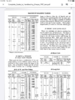

This is my first test of this load to chronograph the recipe and get velocity numbers.

Test number two will most likely be testing in ballistics gelatin.

I am also taking suggestions of other test that can be safely completed to prove out Mr.Revolverguy’s 357 Magnum Bone Crusher.

The loads utilized in this video was operated safely but should not be used in your firearm without loading down by 10% and working up. If you elect to utilize any of this data it is at your own risk, you take full ownership and responsibility for your ammunition.

This got me to thinking if it was this good and still yet very capable today would it not be better in 357 Magnum? Only one problem stood in my way. I could not find one manufacturer producing 357 Magnum Full Wadcutter today. With the popularity of this round surely there would be loads documented some where for the reloading addict like myself. Google enters here, sure there are a lot of people talking about it but nothing well documented. As a matter of fact some of the loads that was documented is downright scary. I searched hi and low and nothing I would trust, most amazing I could not find any type of load even in reloading manuals dating back to the 80’s. This lack of data inspired me and started me on this journey to create Mr.Revolverguy’s 357 Magnum Bone Crusher.

Being a user of Quickload Ballistics for 5 years or more now and with about 4 loading manuals sprawled across my desk I knew I had all the right tools to be successful in my mission.

This is my first test of this load to chronograph the recipe and get velocity numbers.

Test number two will most likely be testing in ballistics gelatin.

I am also taking suggestions of other test that can be safely completed to prove out Mr.Revolverguy’s 357 Magnum Bone Crusher.

The loads utilized in this video was operated safely but should not be used in your firearm without loading down by 10% and working up. If you elect to utilize any of this data it is at your own risk, you take full ownership and responsibility for your ammunition.