Hello,

I learnt from forums and videos that using sandpaper of the correct grit by laying the small piece of sandpaper on the scratch and some surrounding area and using small hammer to lightly hit the area repeatedly would make the matte surface matched the finish of the gun. Tried it and it did work. You only need to be patient as to very lightly hit the spot several times (more like several 10 times) and constantly shift the sandpaper as the used area will become dull little by little. I successfully removed some bright marks I made accidentally using this method.

I think the method is 80-90% perfect comparing to bead blasting. However, with bead blasting, you will need only 5 seconds for small marks. And you don't have to bead blast the whole gun, doing just small area is possible with the correct glass bead size and low air pressure. It sound a lot more difficult than it actually is. The thing is, the whole setup (air compressor, hoses, blasting gun, glass bead, and protective mask will cost you way less than $300.

One thing to look out for when doing bead blasting is that the bead is very small. It can get stuck inside the gun's internals and cause malfunction. You will be able to actually feel it when cocking the hammer. When I did my first bead blasting job, some bead entered and stuck inside the cylinders, it looked normal as the bead was invisible. However I couldn't chamber a round into any cylinder unless I really forced it in. Normal cleaning fixed this easily though.

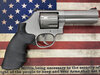

The picture attached is of the gun I bead blasted the area of the frame between the cylinder and trigger.

Good luck,

csirre