You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

80 yrs old surplus ammo!

- Thread starter HankC

- Start date

mcb

Member

I am still shooting 7.62x54R from the 1950's. Yes corrosively primed but a bucket of hot soapy water fixed that after a range session. It is not super consistent but it works well enough for range fodder and I can pretty consistently hit a 6 inch plate at 100 yards with the old iron sights on my Mosin Nagant M44 with it.

The way the ammo was stored will have a big effect on how good it works after long storage. It it was stored in a cool dry place it will still be usable well past the typical 20 year life span most ammo is designed for. It it stored somewhere hot and humid it may not make the 20 yards and still be functional.

The way the ammo was stored will have a big effect on how good it works after long storage. It it was stored in a cool dry place it will still be usable well past the typical 20 year life span most ammo is designed for. It it stored somewhere hot and humid it may not make the 20 yards and still be functional.

jdsingleshot

Member

I bought one box of surplus Berdan primed '06 shells at a give-away price back in the 1970s. I fired a few before deciding I didn't like the idea of jamming steel jacketed bullets down the barrel of my Rem.700. Gave the rest away and have never bought any more surplus ammo.

That said, I have reloads I made in the 1970s that function perfectly. No signs of corrosion. But I guess I'll shoot those up and load some fresh ones.

That said, I have reloads I made in the 1970s that function perfectly. No signs of corrosion. But I guess I'll shoot those up and load some fresh ones.

Nature Boy

Member

- Joined

- Apr 21, 2015

- Messages

- 8,254

If when it was made didn’t matter they wouldn’t put a date stamp on the case head

jonnyc

Member

Sure they would. Military headstamp markings also help identify a particular lot/date, so that defective ammo can be removed from stock without compromising the entire ammo supply.

Jeremy2171

Member

The oldest ammo I've shot thats performed as issues was some 1927 WRA M1 ball ammo. Still shot sub-2 moa.

Powder degrades with age and gets weaker as it uses its own chemical energy to consume itself. I've salvaged some WW1 era M1906 rounds and the powder sorta went poof vs "bang". Low velocity and the oprod hardly moved.

The problem with the aforementioned Turk 8mm ammo is the brass has become brittle. Nothing wrong with the powder at all.

Powder degrades with age and gets weaker as it uses its own chemical energy to consume itself. I've salvaged some WW1 era M1906 rounds and the powder sorta went poof vs "bang". Low velocity and the oprod hardly moved.

The problem with the aforementioned Turk 8mm ammo is the brass has become brittle. Nothing wrong with the powder at all.

Archie

Member

That is my understanding. The change in smokeless gunpowder is slowly becoming inert. Perhaps in some cases (no pun intended) such a round might put a round in the barrel and leave it there. I have seen no reports of detonations of old powder, save the person who stuck a bullet in the barrel, didn't pay attention and fired an active round immediately following.Powder degrades with age and gets weaker as it uses its own chemical energy to consume itself. I've salvaged some WW1 era M1906 rounds and the powder sorta went poof vs "bang". Low velocity and the oprod hardly moved.

Primers have one of two results: They fire or they don't. Can be frustrating, but not particularly dangerous. Unless one is in battle, of course.

Brass is my major concern. If the round fires like it should, but the case fails, the loose gas is a problem. Typically corrosion and case splits are pretty obvious. There are exceptions. Not much way to tell - even a tiny smear of corrosion can be an indicator.Jeremy2171 said:The problem with the aforementioned Turk 8mm ammo is the brass has become brittle. Nothing wrong with the powder at all.

With that said, in the middle 1960s I fired several hundred rounds of "FA 2 16" (Frankfort Arsenal - when it was a government arsenal - February 1916) marked .45 ACP ammunition from a WWII era Ithaca made M1911a1. They all fired fine. No unexpectedly loud rounds, they all worked the action, they all struck pretty much where my rather primitive skills in accuracy predicted. There were a couple rounds stuck in the barrel, but the kids who found the stash in an attic told me they pulled some of the powder for experimental purposes. (Of course, I found out later the ammo was collectable.)

Also, I have two Mannlicher straight pull rifles updated to 8x56Rmm in 1931. I also got 10 boxes of NAZI marked ammunition dated 1938 in the deal. I fired five of those rounds to set myself a baseline for velocity and accuracy - in the last decade. I do not recall any failures to fire and I know nothing blew up. I really do not shoot those (I found another) rifles much, but I found PPU made the ammunition at that time and got some to have. I still have the 1938 stuff for display and if someone cannot live without it.

Yes. Much is corrosively primed. Which demands one must clean the arm after firing. So clean it already.

Yes. There are some arsenals known for sloppy standards and bad ammunition. Pay attention. In general, the NAZI marked ammunition for most anything is 'hot' by our standards, but not dangerously so for the first couple shots. Prolonged firing will accelerate the wear on the arm; so not recommended for collectables.

The oldest ammo I've shot thats performed as issues was some 1927 WRA M1 ball ammo. Still shot sub-2 moa.

Powder degrades with age and gets weaker as it uses its own chemical energy to consume itself. I've salvaged some WW1 era M1906 rounds and the powder sorta went poof vs "bang". Low velocity and the oprod hardly moved.

The problem with the aforementioned Turk 8mm ammo is the brass has become brittle. Nothing wrong with the powder at all.

You have seen this all before. Your fizz theory of gunpowder (ie gunpowder looses it's fizz like soda pop) may be true at the very end of gunpowder lifetime,but well before that, shooters are having over pressure problems and are blowing up firearms.

This was interesting as I was able to acquire the TNO paper that lead to this presentation chart. It is well known that heating gunpowder ages it exponentially. Well known every where except in the shooting community. Accelerated life testing has been going on since I don't know when. I am sure it is pre WW1, and the Navy was conducting accelerate life testing for the munitions on its Battleships and Cruisers well before WW2. And I mean on the ship, it was that critical to know the condition of the powders in the magazines. Stocks were regularly tested on board because the US Navy did not want to duplicate the experience of the foreign capital ships which had magazine blowups with deteriorated gunpowder.

so this 2010 test by TNO is showing that after four weeks of aging 50 cal and 20mm propellant, peak pressures increased 25%.

this is the TNO paper on the subject: AGEING EFFECTS ON PERFORMANCE OF SMALL AND MEDIUM CALIBRE MUNITION

An example how heat reduces the lifetime of smokeless propellants

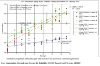

I cannot explain all that is going on in this chart. This is a Reinmetall presentation at an Insensitive Munitions Conference.

But you can see, the single based powders clearly go up in pressure, and the double based propellants go up faster. I don't know what the heck the aged in ammo curves mean. I don't know how Reinmetall determined any of this, maybe by actual test, or with computer models. Reinmetall has been around since the 1880's, built artillery for the Kaiser and the Nazi's. They have ammunition plants all over the world, read about a kaboom of theirs in a South African plant. Reinmetall has a market cap of $9.5 billion and and tens of thousands of employees, so their analysis has a lot more credibility than Jermey's un instrumented one off tests.

This was the real reason Reinmetall was at the symposium, they wanted to sell new and improved gunpowder.

What this shows is as Government WC855 ball powder ages, the peak pressures go up. Maybe not everyone can follow curves and X & Y plots of data, but the text at the bottom explains what is going on above.

This is an Army Research Development Engineering Command chart.

It is fuzzy because Mr Cook had this tossed up on one chart multiple capabilities that ARDEC has, and this just one of the capabilities on the chart. Obviously ARDEC has the ovens and pressure gauges to conduct ballistic stability. This chart is non controversial. It is not shown as something worth talking about, that is, gunpowder peak pressures go up with age, rather, it is more a less a capabilities sales pitch. But as you can see, pressures go up with accelerated lifetime testing.

this was on the web before the Government started withdrawing documents in mass after 911. But this was interesting, it is about the testing going on to determine if ball powders ought to be adopted by the Department of Defense. And this is an accelerated age test.

I am surprised the choices in test conditions, but anytime the propellant is heated for 26 or 42 weeks, the pressures go up.

At some point in deterioration, the gunpowder you own, or in the cases of your cartridges, pressures will go up. And, due to burn rate instabilities, the occasional guns blow up.

Jeremy hates the blow up examples I post. All deniers hate research, except for the psuedo science experiments they conduct and expect us to take seriously. I would rather take my experience of over pressure indications with pull down IMR 4895, and what I have found in the Insensitive Munitions literature on the web over Jeremy's experience. He just did not try hard enough to blow himself up.

I did challenge Jeremy to conduct a more rigorous gunpowder test. That is acquire some old ammunition, at least 150 rounds, shoot around ten over a chronograph and baseline the velocities. And then, pull the bullets and dump the powder of the rest and age it. Age it in a clear bottle at 165 F till the stuff fumes, and hold it a few days more to ensure all the stabilizer is out. Then load the brass with the original charge weights and go out and shoot the stuff over a chronograph before the brass becomes embrittled I think this would be useful as I don't know just how many rounds, or the level of deterioration it takes for old deteriorated gunpowder to detonate. Powder that is fuming would be very deteriorated from what I have read. Might have been the cause of the turret explosion on the USS Iowa. Some of the powder bags were fuming as the charges were being rammed. And I don't think it is immoral to suggest this to someone who earnestly believes that gunpowder fails benignly. And, maybe Jeremy is right about his fizz theory of gunpowder. The results of the test could be an eye opener, one way or another. I was so disappointed when Jeremy turned it down. So to say, Jeremy thinks he can fly, but he won't jump.

The basic problem with gunpowder is, you don't know when it turns bad, till it turns bad. Kind of like cigarettes, you don't know which one, or how many it takes to give you cancer. I can tell you, all the two pack a day guys I knew, few of them made it into their 60's. And they denied smoking caused cancer until, they got it.

Jeremy2171

Member

Lord what a wall of mush.You have seen this all before. Your fizz theory of gunpowder (ie gunpowder looses it's fizz like soda pop) may be true at the very end of gunpowder lifetime,but well before that, shooters are having over pressure problems and are blowing up firearms.

This was interesting as I was able to acquire the TNO paper that lead to this presentation chart. It is well known that heating gunpowder ages it exponentially. Well known every where except in the shooting community. Accelerated life testing has been going on since I don't know when. I am sure it is pre WW1, and the Navy was conducting accelerate life testing for the munitions on its Battleships and Cruisers well before WW2. And I mean on the ship, it was that critical to know the condition of the powders in the magazines. Stocks were regularly tested on board because the US Navy did not want to duplicate the experience of the foreign capital ships which had magazine blowups with deteriorated gunpowder.

so this 2010 test by TNO is showing that after four weeks of aging 50 cal and 20mm propellant, peak pressures increased 25%.

View attachment 1135614

this is the TNO paper on the subject: AGEING EFFECTS ON PERFORMANCE OF SMALL AND MEDIUM CALIBRE MUNITION

An example how heat reduces the lifetime of smokeless propellants

View attachment 1135615

I cannot explain all that is going on in this chart. This is a Reinmetall presentation at an Insensitive Munitions Conference.

View attachment 1135616

But you can see, the single based powders clearly go up in pressure, and the double based propellants go up faster. I don't know what the heck the aged in ammo curves mean. I don't know how Reinmetall determined any of this, maybe by actual test, or with computer models. Reinmetall has been around since the 1880's, built artillery for the Kaiser and the Nazi's. They have ammunition plants all over the world, read about a kaboom of theirs in a South African plant. Reinmetall has a market cap of $9.5 billion and and tens of thousands of employees, so their analysis has a lot more credibility than Jermey's un instrumented one off tests.

This was the real reason Reinmetall was at the symposium, they wanted to sell new and improved gunpowder.

View attachment 1135617

What this shows is as Government WC855 ball powder ages, the peak pressures go up. Maybe not everyone can follow curves and X & Y plots of data, but the text at the bottom explains what is going on above.

This is an Army Research Development Engineering Command chart.

View attachment 1135618

It is fuzzy because Mr Cook had this tossed up on one chart multiple capabilities that ARDEC has, and this just one of the capabilities on the chart. Obviously ARDEC has the ovens and pressure gauges to conduct ballistic stability. This chart is non controversial. It is not shown as something worth talking about, that is, gunpowder peak pressures go up with age, rather, it is more a less a capabilities sales pitch. But as you can see, pressures go up with accelerated lifetime testing.

this was on the web before the Government started withdrawing documents in mass after 911. But this was interesting, it is about the testing going on to determine if ball powders ought to be adopted by the Department of Defense. And this is an accelerated age test.

View attachment 1135619

I am surprised the choices in test conditions, but anytime the propellant is heated for 26 or 42 weeks, the pressures go up.

At some point in deterioration, the gunpowder you own, or in the cases of your cartridges, pressures will go up. And, due to burn rate instabilities, the occasional guns blow up.

Jeremy hates the blow up examples I post. All deniers hate research, except for the psuedo science experiments they conduct and expect us to take seriously. I would rather take my experience of over pressure indications with pull down IMR 4895, and what I have found in the Insensitive Munitions literature on the web over Jeremy's experience. He just did not try hard enough to blow himself up.

I did challenge Jeremy to conduct a more rigorous gunpowder test. That is acquire some old ammunition, at least 150 rounds, shoot around ten over a chronograph and baseline the velocities. And then, pull the bullets and dump the powder of the rest and age it. Age it in a clear bottle at 165 F till the stuff fumes, and hold it a few days more to ensure all the stabilizer is out. Then load the brass with the original charge weights and go out and shoot the stuff over a chronograph before the brass becomes embrittled I think this would be useful as I don't know just how many rounds, or the level of deterioration it takes for old deteriorated gunpowder to detonate. Powder that is fuming would be very deteriorated from what I have read. Might have been the cause of the turret explosion on the USS Iowa. Some of the powder bags were fuming as the charges were being rammed. And I don't think it is immoral to suggest this to someone who earnestly believes that gunpowder fails benignly. And, maybe Jeremy is right about his fizz theory of gunpowder. The results of the test could be an eye opener, one way or another. I was so disappointed when Jeremy turned it down. So to say, Jeremy thinks he can fly, but he won't jump.

The basic problem with gunpowder is, you don't know when it turns bad, till it turns bad. Kind of like cigarettes, you don't know which one, or how many it takes to give you cancer. I can tell you, all the two pack a day guys I knew, few of them made it into their 60's. And they denied smoking caused cancer until, they got it.

No one is denying that heated gun powder doesn't cause excessive pressure... prime reason you don't leave ammo in the sun on range day.

The chart you posted that you claim to not understand clearly shows propellent aged "in" ammo loses pressure as it degrades. Which is exactly what ballisticians say... and what happens in real life.

I have no need or desire to perform a test you want me to do just to make you feel better. Especially when we already know what happens to gunpowder that is degrading. If it's losing it's chemical energy during degradation how can it get "stronger"?

Maybe you should leave the Iowa out of this since it's been pretty much proven the explosion was caused by over ramming the powder bags.

I'm expecting you to respond with another wall of opine and pics of random blown up guns you've found online and claim it was all overpressure ammo ammo doing the damage.

*Sigh*

I found Yugoslav steel cased ammo for a decent price. It was made in the seventies. Same questions asked then as now. It looked good and shot good in my Yugoslav Mauser 24/47. It was a lot of fun. But these warnings of anything older have me being cautious. Eighty years old and looking good. Very tempting to shoot but not to buy. I have learned something here. I am wondering about my not so old storage. But I don’t like corrosive primers any more and they seem to be the main problem with old ammo.

alsaqr

Member

Properly stored in a cool dry place, ammunition will remain serviceable for a long time. In the mid 1970s i came into a huge quantity of .30 caliber military ammunition. After spending a few decades stored in a shaded WV cellar it was brought to OK, where it's stored in an underground bunker. Several years ago i discovered some corroded rounds from a lot manufactured in, i believe, 1942: Destroyed that ammunition.

Recently i fired the last rounds of my .30 caliber ball ammo dated 1944. Rifle is my scoped Remington model 700. Every round hit the 6" target at 125 yards.

i also fired 15 rounds of 1954 armor piercing .30 caliber. There was a deterioration in accuracy since i last fired that ammunition about ten years ago: At 125 yards the best five shot group measured just under 1 3/4 inches.

For many years i trained, advised and assisted the Saudi National Guard in ammunition and EOD stuff. For some reason they had closed the bunker ventilators. There were serious problems with all types of ammunition due to heat.

71 degree C=159.8 degrees F.

Recently i fired the last rounds of my .30 caliber ball ammo dated 1944. Rifle is my scoped Remington model 700. Every round hit the 6" target at 125 yards.

i also fired 15 rounds of 1954 armor piercing .30 caliber. There was a deterioration in accuracy since i last fired that ammunition about ten years ago: At 125 yards the best five shot group measured just under 1 3/4 inches.

For many years i trained, advised and assisted the Saudi National Guard in ammunition and EOD stuff. For some reason they had closed the bunker ventilators. There were serious problems with all types of ammunition due to heat.

71 degree C=159.8 degrees F.

AMraider

Member

- Joined

- Apr 1, 2019

- Messages

- 274

The only problem that I have had was with 1955 Yugo 8mm with factory code 11 that I have posted about before. A Google search of that will produce numerous issues. All other 8mm like 40's Turkish, 50-80's Romanian. 70-90's Yugo have been fine.

In 7.62x54r no problems with Albanian, Czech, Yugo, Romanian and Polish. Chinese 54r resulted in several click/bangs. Thankfully I didn't buy much of that.

The few Swedish 6.5x55 surplus I had didn't always fire on first strike.

Swiss GP-11 7.5x55 is the best.

Inspect carefully and randomly pull down a few. When in doubt pull and part.

In 7.62x54r no problems with Albanian, Czech, Yugo, Romanian and Polish. Chinese 54r resulted in several click/bangs. Thankfully I didn't buy much of that.

The few Swedish 6.5x55 surplus I had didn't always fire on first strike.

Swiss GP-11 7.5x55 is the best.

Inspect carefully and randomly pull down a few. When in doubt pull and part.

Lord what a wall of mush.

No one is denying that heated gun powder doesn't cause excessive pressure... prime reason you don't leave ammo in the sun on range day.

I think you miss entirely what they doing in ballistic stability testing. That powder was not put into a pressure barrel and fired hot. They let it cool down before firing. Heat is used for accelerated aging. It is true that hot cartridges produce more pressure than the same cartridge fired cool.

The chart you posted that you claim to not understand clearly shows propellent aged "in" ammo loses pressure as it degrades.

Not the only chart there. But the only one you use. How about getting your ballistican friend to run some aging tests on cartridges? But you cannot get him to produce that report you need to prove that all commercial ammunition is safe in Garands.

Well explain the in ammo propellant. What is happening to the chemistry and burn rate inside a cartridge case, as compared to an identical sample inside an ammo can? I would like to know. I cannot explain what those lines mean and what "in ammo" is supposed to represent. Not my chart, and I was not there to ask. But you know, right? And since you know, how about explaining how propellants stored in different containers degrade differently. Does propellant in round cans degrade differently from propellant stored in square cans? Be good to know what shape of can to use. What about different colors of cans? Does propellant in green cans degrade different from propellant in red cans? Love to know the right color of can to use.

Which is exactly what ballisticians say... and what happens in real life.

As I have recommended, go an Insensitive Munitions Conference and ask real ballisticans what really happens in the real world.

I have no need or desire to perform a test you want me to do just to make you feel better. Especially when we already know what happens to gunpowder that is degrading. If it's losing it's chemical energy during degradation how can it get "stronger"?

Gunpowder does not burn like a candle. It is an exponential process, and if you ever read anything on the topic, just keeping it burning consistently is a real trick. And since the powders we use are highly dependent on their shape and porosity, changes you can't see with an eyeball make a huge difference in burn rate.

But, I will accept this, at some point in time, the energy content will go down. So, when does it? What do you have that shows the energy content of nitrocellulose versus time.

By the way, tell me about what you know about the explosive potential of gunpowder dust. Since America off shored its textile and other industries, I am sure that dust explosions are now out of the public mind.

bigger coal dust explosion

real coal dust explosion

by the way, this web site provides podcasts and very educational materials about dust explosions:

Dust Incident articles: https://dustsafetyscience.com/articles/

Textile Explosion Case Studies https://dustsafetyscience.com/textile-industries/

Maybe you should leave the Iowa out of this since it's been pretty much proven the explosion was caused by over ramming the powder bags.

The Navy performed a coverup and did everything they could to blame the turret Sailors for the incident. I read the book by the Sandia Corporation investigation team and their analysis of the over ramming explanation offered by the Navy (and a light touch on the Gay suicide theory). Congress did not believe the Gay Suicide explanation, nor any of other accusations of negligence that the Navy claimed the turret crew had committed. So Congress hired Sandia Corporation as an independent investigator. The Navy made a drop fixture to simulate over ramming and even after several hundred drops the powder bags would not ignite. The Sandia team came onsite, and they rearranged the powder tubes in the trim bag (the end bag) so the tubes were longitudinal in the direction of the drop. The very next drop the whole stack of powder bags exploded, disintegrating the test stand. The Sandia book stated the propellant was from WW2, had been stored in hot barges, and at previous times turret crews reported powder bags fuming as the charges were rammed. The fumes were probably nitrogen dioxide gas, which if visible, shows serious depletion of the stabilizer. The book states that those listening on the communications system as the turret crew loaded the guns, that one or two of the turret crew were yelling that the bags were fuming.

Next, Ernie Hanyecz, Turret Two’s leading petty officer suddenly called out, “Mort! Mort! Mort!” Ziegler shouted, “Oh, my God! The powder is smoldering!” About this same time, Hanyecz yelled over the phone circuit, “Oh, my God! There’s a flash!”

Then the turret exploded before the breech was closed. The Sandia team did prove that the longitudinal orientation of those old gunpowder powder tubes plus an impact would cause the propellant to ignite. I have been told, and I have learned enough about UXB to learn, that propellants and explosives sensitize with age.

I'm expecting you to respond with another wall of opine and pics of random blown up guns you've found online and claim it was all overpressure ammo ammo doing the damage.

I expect nothing less than continued denial from you. I do expect you to make your statements on why you believe old gunpowder looses its fizz over time, and I will use what I have to make my case. I am of the opinion that at some point, gunpowder will lose all its energy, but till then, the evidence shows, burn rates shift and create over pressure conditions, including, detonation. You will nit pick, demand information and make "I say so" philosophical arguments. It is up to the readers to decide what is more credible.

alsaqr

Member

The Navy performed a coverup and did everything they could to blame the turret Sailors for the incident. I

A resounding yes!!!

The son of a friend died in that turret.

BTW:

While serving as an EOD advisor the Saudis i conducted a comprehensive study of their ammunition problems; Nearly all were related to storage in hot unventilated bunkers. All of the FN manufactured white bag 155mm propellant in stock became unserviceable due to heat. The tetrytol (TNT and tetryl mixed) bursters in US made 155mm white phosphorous artillery projectiles became desensitized in the heat. The fuzes functioned but the rounds failed to burst on impact.

Exposed to high heat, TNT exudes from artillery rounds and bombs heat leaving a cavity. Artillery projectiles having a cavity are prone to explode on firing. After Desert Storm an 8" artillery projectile exploded in the tube at Fort Sill. i drove by and looked at that gun, about three feet directly in front of the barrel reinforcement fragmented. Thankfully, no member of the crew were seriously injured. That projectile had been retrograded from Saudi after spending one summer in the hot desert.

Prior to the US Army being designed the single manager for ammunition the US Navy had a career program for ammunition officers. Those selected for the program went to school for years and served under ammunition safety officers before being assigned a billet. i knew a US Navy ammunition safety officer. Drank a lot of beer with the man and was absolutely amazed at his knowledge of ammunition. That program went away when the single manager went into effect.

Jeremy2171

Member

I think you miss entirely what they doing in ballistic stability testing. That powder was not put into a pressure barrel and fired hot. They let it cool down before firing. Heat is used for accelerated aging. It is true that hot cartridges produce more pressure than the same cartridge fired cool.

Not the only chart there. But the only one you use. How about getting your ballistican friend to run some aging tests on cartridges? But you cannot get him to produce that report you need to prove that all commercial ammunition is safe in Garands.

Well explain the in ammo propellant. What is happening to the chemistry and burn rate inside a cartridge case, as compared to an identical sample inside an ammo can? I would like to know. I cannot explain what those lines mean and what "in ammo" is supposed to represent. Not my chart, and I was not there to ask. But you know, right? And since you know, how about explaining how propellants stored in different containers degrade differently. Does propellant in round cans degrade differently from propellant stored in square cans? Be good to know what shape of can to use. What about different colors of cans? Does propellant in green cans degrade different from propellant in red cans? Love to know the right color of can to use.

As I have recommended, go an Insensitive Munitions Conference and ask real ballisticans what really happens in the real world.

Gunpowder does not burn like a candle. It is an exponential process, and if you ever read anything on the topic, just keeping it burning consistently is a real trick. And since the powders we use are highly dependent on their shape and porosity, changes you can't see with an eyeball make a huge difference in burn rate.

But, I will accept this, at some point in time, the energy content will go down. So, when does it? What do you have that shows the energy content of nitrocellulose versus time.

By the way, tell me about what you know about the explosive potential of gunpowder dust. Since America off shored its textile and other industries, I am sure that dust explosions are now out of the public mind.

bigger coal dust explosion

real coal dust explosion

by the way, this web site provides podcasts and very educational materials about dust explosions:

Dust Incident articles: https://dustsafetyscience.com/articles/

Textile Explosion Case Studies https://dustsafetyscience.com/textile-industries/

The Navy performed a coverup and did everything they could to blame the turret Sailors for the incident. I read the book by the Sandia Corporation investigation team and their analysis of the over ramming explanation offered by the Navy (and a light touch on the Gay suicide theory). Congress did not believe the Gay Suicide explanation, nor any of other accusations of negligence that the Navy claimed the turret crew had committed. So Congress hired Sandia Corporation as an independent investigator. The Navy made a drop fixture to simulate over ramming and even after several hundred drops the powder bags would not ignite. The Sandia team came onsite, and they rearranged the powder tubes in the trim bag (the end bag) so the tubes were longitudinal in the direction of the drop. The very next drop the whole stack of powder bags exploded, disintegrating the test stand. The Sandia book stated the propellant was from WW2, had been stored in hot barges, and at previous times turret crews reported powder bags fuming as the charges were rammed. The fumes were probably nitrogen dioxide gas, which if visible, shows serious depletion of the stabilizer. The book states that those listening on the communications system as the turret crew loaded the guns, that one or two of the turret crew were yelling that the bags were fuming.

Next, Ernie Hanyecz, Turret Two’s leading petty officer suddenly called out, “Mort! Mort! Mort!” Ziegler shouted, “Oh, my God! The powder is smoldering!” About this same time, Hanyecz yelled over the phone circuit, “Oh, my God! There’s a flash!”

Then the turret exploded before the breech was closed. The Sandia team did prove that the longitudinal orientation of those old gunpowder powder tubes plus an impact would cause the propellant to ignite. I have been told, and I have learned enough about UXB to learn, that propellants and explosives sensitize with age.

I expect nothing less than continued denial from you. I do expect you to make your statements on why you believe old gunpowder looses its fizz over time, and I will use what I have to make my case. I am of the opinion that at some point, gunpowder will lose all its energy, but till then, the evidence shows, burn rates shift and create over pressure conditions, including, detonation. You will nit pick, demand information and make "I say so" philosophical arguments. It is up to the readers to decide what is more credible.

I just love how you always come in with your random photos of blown guns. Usually already prepared...and then post random opinions not related the OPs question.I think you miss entirely what they doing in ballistic stability testing. That powder was not put into a pressure barrel and fired hot. They let it cool down before firing. Heat is used for accelerated aging. It is true that hot cartridges produce more pressure than the same cartridge fired cool.

Not the only chart there. But the only one you use. How about getting your ballistican friend to run some aging tests on cartridges? But you cannot get him to produce that report you need to prove that all commercial ammunition is safe in Garands.

Well explain the in ammo propellant. What is happening to the chemistry and burn rate inside a cartridge case, as compared to an identical sample inside an ammo can? I would like to know. I cannot explain what those lines mean and what "in ammo" is supposed to represent. Not my chart, and I was not there to ask. But you know, right? And since you know, how about explaining how propellants stored in different containers degrade differently. Does propellant in round cans degrade differently from propellant stored in square cans? Be good to know what shape of can to use. What about different colors of cans? Does propellant in green cans degrade different from propellant in red cans? Love to know the right color of can to use.

As I have recommended, go an Insensitive Munitions Conference and ask real ballisticans what really happens in the real world.

Gunpowder does not burn like a candle. It is an exponential process, and if you ever read anything on the topic, just keeping it burning consistently is a real trick. And since the powders we use are highly dependent on their shape and porosity, changes you can't see with an eyeball make a huge difference in burn rate.

But, I will accept this, at some point in time, the energy content will go down. So, when does it? What do you have that shows the energy content of nitrocellulose versus time.

By the way, tell me about what you know about the explosive potential of gunpowder dust. Since America off shored its textile and other industries, I am sure that dust explosions are now out of the public mind.

by the way, this web site provides podcasts and very educational materials about dust explosions:

Dust Incident articles: https://dustsafetyscience.com/articles/

Textile Explosion Case Studies https://dustsafetyscience.com/textile-industries/

The Navy performed a coverup and did everything they could to blame the turret Sailors for the incident. I read the book by the Sandia Corporation investigation team and their analysis of the over ramming explanation offered by the Navy (and a light touch on the Gay suicide theory). Congress did not believe the Gay Suicide explanation, nor any of other accusations of negligence that the Navy claimed the turret crew had committed. So Congress hired Sandia Corporation as an independent investigator. The Navy made a drop fixture to simulate over ramming and even after several hundred drops the powder bags would not ignite. The Sandia team came onsite, and they rearranged the powder tubes in the trim bag (the end bag) so the tubes were longitudinal in the direction of the drop. The very next drop the whole stack of powder bags exploded, disintegrating the test stand. The Sandia book stated the propellant was from WW2, had been stored in hot barges, and at previous times turret crews reported powder bags fuming as the charges were rammed. The fumes were probably nitrogen dioxide gas, which if visible, shows serious depletion of the stabilizer. The book states that those listening on the communications system as the turret crew loaded the guns, that one or two of the turret crew were yelling that the bags were fuming.

Next, Ernie Hanyecz, Turret Two’s leading petty officer suddenly called out, “Mort! Mort! Mort!” Ziegler shouted, “Oh, my God! The powder is smoldering!” About this same time, Hanyecz yelled over the phone

Then the turret exploded before the breech was closed. The Sandia team did prove that the longitudinal orientation of those old gunpowder powder tubes plus an impact would cause the propellant to ignite. I have been told, and I have learned enough about UXB to learn, that propellants and explosives sensitize with age.

I expect nothing less than continued denial from you. I do expect you to make your statements on why you believe old gunpowder looses its fizz over time, and I will use what I have to make my case. I am of the opinion that at some point, gunpowder will lose all its energy, but till then, the evidence shows, burn rates shift and create over pressure conditions, including, detonation. You will nit pick, demand information and make "I say so" philosophical arguments. It is up to the readers to decide what is more credible.

Now you have derailed this thread..like you do in many others with takes of insensitive munitions..new powder production sales pitches.

Now you've even managed to bring up the USS Iowa explosion as an "ah ha!"

Finally we now have to see your wall if text about coal dust explosions.

Which is totally relevant to 1940s yugo 8mm ball ammo.

Scooter22

Member

Jeremy2171

Member

BushMaster-15

member

Still using 42 44 53 and 1954 M2 cases along with 173 gr. bullets and have #25 reloads on them . Have shot and annealed every #3 Rd. reload and haven't lost a single case . Improperly stored ammo NO one should be buying shooting or even considering scraping the brass for !.

However " Properly stored Ammo " is another matter all together AGE has NO effect on the Brass but corrosion most certainly does !.

The two lower left and right was typical of the lot of 3K I got and as You can see they cleaned up nicely and are working far beyond their expected life cycle . I'm 0.5 grains under max load ,so their NOT babied . I haven't even had a lose primer pocket

After the #3 minute ultrasonic bath .

I also have had Zero Problems with any of My older 53,54, 57,64 7.62X51mm and they have the same # of firings as do My 7.62X63mm aka M2 Ball .

However " Properly stored Ammo " is another matter all together AGE has NO effect on the Brass but corrosion most certainly does !.

The two lower left and right was typical of the lot of 3K I got and as You can see they cleaned up nicely and are working far beyond their expected life cycle . I'm 0.5 grains under max load ,so their NOT babied . I haven't even had a lose primer pocket

After the #3 minute ultrasonic bath .

I also have had Zero Problems with any of My older 53,54, 57,64 7.62X51mm and they have the same # of firings as do My 7.62X63mm aka M2 Ball .

BushMaster-15

member

PS : I've got lead sealed wooden crated 8mm Mauser German manufactured WWll ammo and also shoot it in My 98's .

Not a single problem with any of it either . I had some silly bugger on a gun forum try and tell Me ,that brass had a #20 year self life

So clearly everything you read and see on the Internet ISN'T GOSPEL

So clearly everything you read and see on the Internet ISN'T GOSPEL

Not a single problem with any of it either . I had some silly bugger on a gun forum try and tell Me ,that brass had a #20 year self life

So clearly everything you read and see on the Internet ISN'T GOSPEL

So clearly everything you read and see on the Internet ISN'T GOSPEL PS : I've got lead sealed wooden crated 8mm Mauser German manufactured WWll ammo and also shoot it in My 98's .

Not a single problem with any of it either . I had some silly bugger on a gun forum try and tell Me ,that brass had a #20 year self lifeSo clearly everything you read and see on the Internet ISN'T GOSPEL

The shelf lifetime of gunpowder is "unknown". It varies so much, due to acids left in the nitrocellulose, that there is no good mathematical model nor predictive technique for lifetime. Instead, those militaries that can afford it, pay people to inspect and test.

These charts came from a 1969 and 1970 Munitions Symposium that I found on DTIC. Incidentally, lots of documents that were in the public domain were pulled back, and not knowing this would happen, I did not save the entire symposium packages. I just saved these charts.

But what you do see is that Ammunition Specialists pull ammunition lots, test the stability of the gun powder, and discard the lot once it fails their stability tests. These lots are from WW2, so they would have been from 27 to 24 years old in 1969, and they are fuming because they have used up the stabilizer in the gunpowder.

This one was good as it shows a span of fuming times, and the dates of manufacture

As an aside, it used to be that the documents on the Defense Acquistion University website were downloadable. Now, you can see the titles, but you cannot open them. But, even with the titles, it should be obvious that a lot of people are examining, testing, sorting, etc, through DoD munitions

Munitions and Explosives Safety DAU

I clicked through the various sub forums, could see titles, was blocked from opening the documents. I have a 2010 version of the Ammunition Reference Guide, but now, the 2020 version its blocked. Very frustrating.

Luckily, these old TM's are still out there:

TM 9-1300-214 Military Explosives

Section7-7 Nitrocellulose

q. Nitrocellulose, even when highly purified, is much less stable than most of the non initiating military high explosives, as judged by elevated temperature test. It appears to undergo very slow decomposition even at ordinary temperatures, the rate of decomposition increasing 3.71 times with each increase in temperature of 10 ºC. The presence of moisture increases the rate of decomposition considerably and the presence of free acid or alkali has an even more pronounced effect.

r. The great care taken in the purification of nitrocellulose is due to the necessity of removing impurities that are much less stable than nitrocellulose itself. Cellulose sulfate is unstable, with respect to heat and moisture.

US Ammunition manufacturer's used to warranty their ammunition for 10 years, last I looked, it was down to one year! The market will buy anything so they don't have to provide realistic warranties. I did read an article where the writer claimed that CIP had a 20 year shelf life requirement for gunpowder. I have not been able to access a CIP standards database, but something that is very different from SAAMI standards and CIP standards is that these European standards have the force of law. Manufacturers have to submit their guns and ammunition to the proof house for testing. And the ammunition lot fails, the lot is rejected. Don't know what happens after that, obviously it cant be sold in Europe, but probably it gets sold to Americans who will buy anything!

Interesting short videos of the proof testing process for a shotgun and a S&W revolver. American made firearms have to pass the proof test to be sold in Europe

EPREUVES VIDÉOS

Based on discussions with a real Insensitive Munitions expert, twenty years is a common DoD lifetime requirement for munitions. And they have stability tests, such as accelerated aging, where the ballistic stability of the propellant are tested.

I thought this was interesting.

MIL-P-3984J MILITARY Specification on Propellants for Small Arms Ammunition.

5.2.1 Level A All level A containers shall have a printed label affixed to the side with the following information:

AFTER FIVE YEARS FROM DATE OF MANUFACTURE, APPROVAL BY RESPONSIBLE PROCURING AGENCY IS REQUIRED PRIOR TO THE LOADING OF THIS PROPELLANT INTO SMALL ARMS AMMUNITION

5.2.2 Level C Containers shall be marked on the side with the same markings as required for the side of the box shown on Drawing 8858848. DOT markings shall be in accordance with CFR 49, section 173.93 (f) and the applicable Hazardous Component

Safety Data Statement.

5.2.3 Special markings All level C containers shall have a printed label affixed to the side with the following information:

AFTER TWO YEARS FROM DATE OF MANUFACTURE, APPROVAL BY THE RESPONSIBLE PROCURING AGENCY IS REQUIRED PRIOR TO THE LOADING OF THIS PROPELLANT INTO SMALL ARMS AMMUNITION

What you see is that propellant that has been sitting in storage containers has a "shelf" life. What I presume is that the Procuring Agency will require ballistic stability tests, section 400 Mil Std 286 Propellants, Solid, Sampling Examination and Test, and that the gunpowder has to pass those tests, before being loading into cases. I provided a link to Mil Std 286, and it is worth looking at the test procedures, and it is worth comparing and contrasting the amount of laboratory equipment a Test Laboratory uses to determine ballistic stability, versus what Jeremy did with some old, undefined powder, and a chronograph. Which shows a deeper understanding of the thermochemical issues of gunpowder?

I often give shooters/reloaders the advice to shoot up their ammunition and powder before it is 20 years old. I have been giving the advice not to load up ammunition and have it sit around for years and years. It is better to load cases when you expect to shoot the stuff. That way, you don't lose brass due to brass embrittlement from NOx. I have lost a number of good cases that I loaded in the late 80's and did not shoot till 2017 or so. The powder was deteriorating in the case. Twenty years is not based on any hard and fast line in the sand. Neither is the advice to replace tires older than six years old hard and fast. However, if your commercial truck blows its ten year old tire, and hurts someone, (as has happened), expect a lawsuit. The UK got tired (pun intended!) of commercial trucks killing people when their old tires blew, so the UK passed a law requiring 10 yr + tires to be removed. I am sure the deniers in the truck industry were loud and vocal about how the lifetime of a tire is forever. But for ammunition, 20 years is pretty old.

Army Not Producing Enough Ammunition

http://www.nationaldefensemagazine.org/archive/2003/May/Pages/Army_Not3866.aspx

Regardless of what the Army decides to do with its industrial base, the fundamental issue does not change: the Army needs to produce more war reserve ammunition, Naughton said. Time is running out, he said. “Most of the ammunition in the stockpile today was built 20 years ago during the Cold War buildup.” Most rounds are designed to have a shelf life of 20 years. “We are outside the envelope of the shelf life on 40 percent or more of our existing ammunition. The rest is rapidly approaching the end of its shelf life.”

Ammunition does not “go bad” overnight, after it reaches a certain age, but “once it’s over 20 years old, the reliability rapidly degrades,” said Naughton. Within a few years, it will become increasingly difficult to shoot it. “You can predict that you’ll lose 7-8 percent of the ammo after the 20-year mark.”*

To replace the obsolete rounds, the Army would have to produce 100,000 tons of war reserve ammunition a year for the next seven years. Past that point, it would need 50,000 tons to 60,000 tons a year to sustain the stockpile. That represents about “half the level of the Cold War buildup,” he said.

* I think what is meant, 7-8 percent per year after 20 years.

When I thought ammunition lasted forever, because that is what I read in the inprint magazines, I purchased and shot thousands of rounds of surplus 6.5 Swede, 7mm Mauser, 303 British, 7.62 Nagant, 30-06 and 308. I purchased surplus for my collection of military rifles. And I had high pressure indications, and I did not know what that meant, because the elites of the shooting community were out there claiming gunpowder last forever and fails benignly. I had 303 Brit and 8mm ammunition so hot they pierced primers and the firing pin would snap back. I am glad I never cracked a lug or developed receiver seat set back. I am sure some have. Luckily, I never experienced a detonation event. I do know shooters who have. Old ammunition is prone to detonating, very rare, but it happens.

It is good if the buyer of old ammunition is aware of the signs of deteriorating ammunition, is able to recognize the signs. The gross indications are corrosion inside the case, velocities higher than spec, and obvious signs of high pressures. These are all indications of deteriorated gunpowder, and with cases full of deteriorated gunpowder it is prudent to disassemble the stuff and dump the powder. If the cases are corroded, it is best not to re use them.

But, its up to you. Every day, one million fentanyl/opioid users get high, sometimes several times a day, and only 175 of them die. (the web does not have firm estimate of fentanyl users, but with over 100,000 dying per year, I think 1 million active users is a good guess) Not a single one of the alive ones think what they are doing is too risky to quit. There are those who have that mentality when it comes to all risks, and nothing anyone says is going to change their behavior.

Last edited:

BushMaster-15

member

The shelf lifetime of gunpowder is "unknown". It varies so much, due to acids left in the nitrocellulose, that there is no good mathematical model nor predictive technique for lifetime. Instead, those militaries that can afford it, pay people to inspect and test.

These charts came from a 1969 and 1970 Munitions Symposium that I found on DTIC. Incidentally, lots of documents that were in the public domain were pulled back, and not knowing this would happen, I did not save the entire symposium packages. I just saved these charts.

But what you do see is that Ammunition Specialists pull ammunition lots, test the stability of the gun powder, and discard the lot once it fails their stability tests. These lots are from WW2, so they would have been from 27 to 24 years old in 1969, and they are fuming because they have used up the stabilizer in the gunpowder.

View attachment 1136825

This one was good as it shows a span of fuming times, and the dates of manufacture

View attachment 1136826

As an aside, it used to be that the documents on the Defense Acquistion University website were downloadable. Now, you can see the titles, but you cannot open them. But, even with the titles, it should be obvious that a lot of people are examining, testing, sorting, etc, through DoD munitions

Munitions and Explosives Safety DAU

I clicked through the various sub forums, could see titles, was blocked from opening the documents. I have a 2010 version of the Ammunition Reference Guide, but now, the 2020 version its blocked. Very frustrating.

Luckily, these old TM's are still out there:

TM 9-1300-214 Military Explosives

Section7-7 Nitrocellulose

q. Nitrocellulose, even when highly purified, is much less stable than most of the non initiating military high explosives, as judged by elevated temperature test. It appears to undergo very slow decomposition even at ordinary temperatures, the rate of decomposition increasing 3.71 times with each increase in temperature of 10 ºC. The presence of moisture increases the rate of decomposition considerably and the presence of free acid or alkali has an even more pronounced effect.

r. The great care taken in the purification of nitrocellulose is due to the necessity of removing impurities that are much less stable than nitrocellulose itself. Cellulose sulfate is unstable, with respect to heat and moisture.

US Ammunition manufacturer's used to warranty their ammunition for 10 years, last I looked, it was down to one year! The market will buy anything so they don't have to provide realistic warranties. I did read an article where the writer claimed that CIP had a 20 year shelf life requirement for gunpowder. I have not been able to access a CIP standards database, but something that is very different from SAAMI standards and CIP standards is that these European standards have the force of law. Manufacturers have to submit their guns and ammunition to the proof house for testing. And the ammunition lot fails, the lot is rejected. Don't know what happens after that, obviously it cant be sold in Europe, but probably it gets sold to Americans who will buy anything!

Interesting short videos of the proof testing process for a shotgun and a S&W revolver. American made firearms have to pass the proof test to be sold in Europe

EPREUVES VIDÉOS

Based on discussions with a real Insensitive Munitions expert, twenty years is a common DoD lifetime requirement for munitions. And they have stability tests, such as accelerated aging, where the ballistic stability of the propellant are tested.

I thought this was interesting.

MIL-P-3984J MILITARY Specification on Propellants for Small Arms Ammunition.

What you see is that propellant that has been sitting in storage containers has a "shelf" life. What I presume is that the Procuring Agency will require ballistic stability tests, section 400 Mil Std 286 Propellants, Solid, Sampling Examination and Test, and that the gunpowder has to pass those tests, before being loading into cases. I provided a link to Mil Std 286, and it is worth looking at the test procedures, and it is worth comparing and contrasting the amount of laboratory equipment a Test Laboratory uses to determine ballistic stability, versus what Jeremy did with some old, undefined powder, and a chronograph. Which shows a deeper understanding of the thermochemical issues of gunpowder?

I often give shooters/reloaders the advice to shoot up their ammunition and powder before it is 20 years old. I have been giving the advice not to load up ammunition and have it sit around for years and years. It is better to load cases when you expect to shoot the stuff. That way, you don't lose brass due to brass embrittlement from NOx. I have lost a number of good cases that I loaded in the late 80's and did not shoot till 2017 or so. The powder was deteriorating in the case. Twenty years is not based on any hard and fast line in the sand. Neither is the advice to replace tires older than six years old hard and fast. However, if your commercial truck blows its ten year old tire, and hurts someone, (as has happened), expect a lawsuit. The UK got tired (pun intended!) of commercial trucks killing people when their old tires blew, so the UK passed a law requiring 10 yr + tires to be removed. I am sure the deniers in the truck industry were loud and vocal about how the lifetime of a tire is forever. But for ammunition, 20 years is pretty old.

Army Not Producing Enough Ammunition

http://www.nationaldefensemagazine.org/archive/2003/May/Pages/Army_Not3866.aspx

* I think what is meant, 7-8 percent per year after 20 years.

When I thought ammunition lasted forever, because that is what I read in the inprint magazines, I purchased and shot thousands of rounds of surplus 6.5 Swede, 7mm Mauser, 303 British, 7.62 Nagant, 30-06 and 308. I purchased surplus for my collection of military rifles. And I had high pressure indications, and I did not know what that meant, because the elites of the shooting community were out there claiming gunpowder last forever and fails benignly. I had 303 Brit and 8mm ammunition so hot they pierced primers and the firing pin would snap back. I am glad I never cracked a lug or developed receiver seat set back. I am sure some have. Luckily, I never experienced a detonation event. I do know shooters who have. Old ammunition is prone to detonating, very rare, but it happens.

It is good if the buyer of old ammunition is aware of the signs of deteriorating ammunition, is able to recognize the signs. The gross indications are corrosion inside the case, velocities higher than spec, and obvious signs of high pressures. These are all indications of deteriorated gunpowder, and with cases full of deteriorated gunpowder it is prudent to disassemble the stuff and dump the powder. If the cases are corroded, it is best not to re use them.

But, its up to you. Every day, one million fentanyl/opioid users get high, sometimes several times a day, and only 175 of them die. (the web does not have firm estimate of fentanyl users, but with over 100,000 dying per year, I think 1 million active users is a good guess) Not a single one of the alive ones think what they are doing is too risky to quit. There are those who have that mentality when it comes to all risks, and nothing anyone says is going to change their behavior.

I've got M1 Ball ammo ( I DON'T shoot because of collector value ) Cal. .30 M1906 with Cupronickel CUNi jacketed 150 gr.

Those cartridges predate the Cal. .30 M1 1906 by several years ,as those are 173 gr. GM jacketed guilding metal. Copper was being conserved . Then onto 1937-38 when the Cal. .30 M2 was brought out with 150 gr. bullets with stannic stained jackets so as to be distinguished from M1 173 gr. ammo . To the best of MY knowledge 1941 was the Last year general M1 ammo was produced .

Bruce Hodgdon would totally disagree with you as to powder life and I also KNOW that powder properly stored can exist for decades .

Is it as good as Freshly manufactured NO . Is it Stable YES . Does it deteriorate ?, to a degree over time . It does accelerate or decay quicker as temperature and or moisture increases over a prolonged period . Old Nitrocellulose film has NO stabilizers and is on ester base so very highly flammable and dangerous . DITTO with Smokeless Powder ,IF the aforementioned is allowed to take place . Upon opening a canister of powder ,IF one sees FUMING fine particulates or smells and acidic odor sour smelling I advice IMMEDIATELY PROPERLY DISPOSING OF IT . Modern powders have much much better stabilizers than their older cousins and shelf life stabilization is OUTSTANDING .

Take the Heat stable Varget , Staball and Enduron along with others ,why do You think they preform with such consistency ?. Heat Stable !.

Regarding the production of the smokeless powder, Olsen and his co-workers developed a process to manufacture a smokeless powder in a manner so as to secure a superior product irrespective (within limits) of the base. The base may be nitrocellulose, and its kind and character, as well as composition, may be varied; it may be wholly or partially purified fibrous nitrocellulose; it may be dense colloided nitrocellulose in the form of existing powder, or of good, poor or indifferent stability . Also, during the course of operations, the product is purified and stabilized, and the incorporation of additional ingredients, such as stabilizers and modifying agents (burning regulators or accelerators), are added . By doing so regulates powders properties within the specification of purpose of manufacturing .

The finishing operations are similar to the ones that are usually carried out during the manufacture of a single-base smokeless powder. After cooling of the medium, and when the grains have become consolidated or hardened, they may be subjected to a screening operation, in which the over-sized can be sent back for reworking and the screened grains can be subjected to a wringing operation and thereafter to a drying operation. The grains may be surface treated prior to drying with a suitable modifying agent, such as a deterrent or an accelerator. The coating may comprise nitroglycerin which acts as an accelerator; in that it allows the powder to be more readily ignitable and also acts as a waterproofing agent, rendering the powder non-hygroscopic. A suitable deterrent such as dibutylphthalate may be used along with the nitroglycerin or other accelerator and waterproofing agent. The grains may be then dried and glazed in the usual manner and thereafter blended if desired .

MY personal recommendation on Smokeless powder is ,upon opening a canister USE the canister within 10 years time . ALWAYS replace the seal in addition to the lid ,store in a cool place out of sunlight . NO one should have any problems with deterioration .

I still have Hodgdon's Surplus H870 from the 60's and still loading with it ,NO deterioration whatsoever !. Up until #3 years ago I also had surplus IMR 4831 from WWll and never had any issues with it either .

Powder must have air aka oxidation and or moisture excessive heat to begin releasing sulfuric and nitric compounds from the cellulose ,at that stage it becomes fireworks or fertilizer .

IF I could get a nickle from every knothead who told Me an M1 will tear up your cases ,you won't get #5 reloads on them and powder will blowup in your cabinet after #5 years ,I could BUY BILL GATES !. Same people who say Brass ages and hardens isn't reliable gonna blow up on you . Being a former chemist I DO KNOW a bit about chemicals and their behavior . Having batched powder for a living also qualifies MY statements .

Many might be surprised smokeless powder is MADE IN WATER . https://www.scielo.br/j/jatm/a/F5jvxSkXkVgq7ZTVMmbHjnR/?lang=en

Olen F Tibbets 1936

Bruce Hodgdon would totally disagree with you as to powder life and I also KNOW that powder properly stored can exist for decades

Yes powder can last decades. Badly made powder, there are recalls on Dupont and Accurate Arms powders that are less than one decade old. Powder lifetime is unpredictable. And I don’t disagree with anything Hodgdon is saying here:

https://www.hodgdonreloading.com/gunpowder-stability

The following information is provided as an introduction on the stability, storage, and safe handling of modern smokeless propellant.

Smokeless Propellant

The main ingredient of smokeless propellant, comprising from about 55% to 90% of the composition, is nitrocellulose. The process of creating nitrocellulose leaves remnant acid in the material. This acid immediately starts decomposing the finished product. Left alone the decomposition will reach the stage where the propellant becomes unstable and self-ignites. This process resulted in massive explosions at U.S. Government arsenals after World War I.

To increase the life of the smokeless propellant, a stabilizing chemical is used. This “stabilizer” reacts with the acid to slow down the decomposition process. However, as the stabilizer reacts with the acid it is consumed. After the stabilizer is totally consumed, the propellant is no longer protected from the internal acid.

The entire stabilizer / decomposition process is a time and temperature function – the higher the temperature, the shorter the safe life of the powder. Even moderate temperature, over extended time, leads to propellant decomposition. As a rule of thumb, any temperature over that which is comfortable to a person is accelerating the decomposition of smokeless propellants.

Under proper storage, modern smokeless powder can last for decades. However, this does not mean the reloader can ignore how the powder is stored, particularly if in an uncontrolled environment such as a garage or storage building.

It is good to see powder makers warning about old deteriorated gunpowder auto combusting. But there some other phenomena, bad things, that will happen with old gunpowder. Namely pressure rises and the occasional detonation event. While storage is important, gunpowder is still breaking down, even in nice storage. Just takes longer. A bud of mine got out of Highpower. He was selling mid 1990's unopened, seals never broken, Vihtavuori rifle powders. The powders have never left his nice air conditioned house. Another bud purchased a keg, broke the seal, and the powder was bad.

You are obviously above average in education and technical knowledge. And you do understand gunpowder deteriorates. And I was told, the deterioration rate follows the Arrhenius Equation, where temperature is in the coefficient. The higher the temperature, the deterioration accelerates exponentially. It is great when a mathematical equation can model real life.

Something neither Hodgdon, nor the very interesting paper link you posted discussed, was burn rate and how grain shape, surface condition, and chemical changes affect burn rate. Total energy content of the grain lessens in time, but, due to grain, surface, and changes in propellant homogeneity, burn rates will spike and become unstable. Incidentally, with double based powders, water in the atmosphere wicks nitroglycerine to the surface, which spikes the initial burn rate. Nitrogylcerine also attacks the nitrocellulose, which is why double based powders have less than half the lifetime of single base. Anything ionic attacks the double bonds of the NO molecules. Given the amount of humidity out there, there is a lot of water in the air.

If you can still do the calculations, with PV=nRT, just how many water molecules are in an cubic cm of air? Billions, or millions? Molecules are little buggers, has to be a lot.

This has only a couple of sentences on the consequences of changes in grain shape, still it confirms that burn rates will move from deflagration to detonation given the right circumstances.

Solid Propellants

K.O. Hartman, Scott Morrow, in Encyclopedia of Physical Science and Technology (Third Edition), 2003

I Characteristics

Three major applications of solid propellants are driving a projectile from a gun or similar device at high velocity, powering a rocket motor, and generating gas for actuation of mechanical devices. Many different types of solid propellants are needed to match these diverse applications. The original propellant, of course, was black powder, which is no longer used as a major gun propellant.

Propellant grains of given physical properties, composition, and configuration can be expected to burn in a predetermined manner. The burning rate is selected for a particular condition of use. Thermal diffusivity into the propellant is an important factor in controlling the regression rate. Under normal conditions of propellant combustion, the burning process proceeds in a controlled manner. It is possible for the deflagration under certain conditions to accelerate, however, generating a pressure wave that is transformed to a shock wave, which produces a detonation. This deflagration-to-detonation process is referred to as a DDT. It is highly undesirable in a propellant where controlled rather than precipitate energy release is desired.

In spite of the difference in the way in which solid propellants and explosives release their energy under normal conditions of use, they are closely allied chemically. They both contain premixed oxidizer and fuel, either on the molecular level or as a mixture of chemical compounds. The distinction is kinetic rather than thermodynamic. In fact many compositions can function as either a propellant or explosive, depending only on the mode of initiation. Many ingredients are common to both, such as cyclomethylenetrinitramine (RDX), cyclomethylenetetranitramine (HMX), nitroguanidine, ammonium nitrate, as well as ammonium perchlorate and aluminum. Propellants are almost always mixtures, whereas explosives, depending on the application, can be largely single compounds such as RDX or HMX. While detonability is an essential feature in explosives, it is undesirable in propellants. The scale on which the oxidizer and fuel are mixed has a profound effect on this characteristic. In compounds such as HMX and nitroglycerine the fuel and oxidizer are “premixed” in the molecule itself (on the angstrom scale). These materials will sustain a detonation wave at velocities of ∼10 km/sec and have critical diameters of less than 1 cm. In contrast, in composite propellants (often composed of ammonium perchlorate and rubber binders) where the oxidizer and fuel are mostly contained in separate molecules, the mixing is on the micrometer scale. These compositions have critical diameters on the order of 5 ft, even though their energy is roughly comparable to that of the molecular explosives. The shock pressure required to initiate a detonation is also much higher for the composite propellants.

Gun propellants are composed of nitrocellulose (NC) and other constituents. Propellants containing NC as the main ingredient are referred to as single base; double-base propellants contain NC plasticized with nitroglycerin, and triple-base propellants are formulated by the addition of nitroguanidine to a double-base composition. Diphenylamine or ethyl centralite is used as a stabilizer in these propellants. Dinitrotoluene, dibutyl phthalate, ethylene dimethacrylate, and methyl centralite are added as deterrents to inhibit the initial burning rate of propellant grains. Other additives serve as lubricants, opacifiers, erosion inhibitors, burning-rate modifiers, and agents to improve the processing characteristics of propellant mixtures and to promote their “curing.” Experimental gun propellants have been formulated in which nonenergetic acrylic rubber binder has been used in place of energetic NC. Although double base is used as a binder in some rocket propellants, plastic, resinous, or polymeric ones are more common. More frequently used polymeric binders for composite rocket propellants are polyurethanes and polybutadienes. Many composite propellants contain powdered ammonium perchlorate (AP) oxidizer and fine-particle-size aluminum metal as a fuel. These propellants have a heterogeneous structure in which the oxidizer particles are surrounded by fuel-rich regions. When AP and aluminum metal are incorporated in double-base propellant, it is referred to as a composite modified double-base (CMDB) type. Mechanical strength is important in both gun and rocket propellants. In the case of guns, if the propellant grains break up during combustion, the burning rate can accelerate dangerously, causing over pressurization and possibly bursting of the barrel. Small cracks or defects in a rocket motor grain can lead to equally disastrous results.

If you work in the propellant industry, if you know someone at a National Test Range, or who has shot a lot of old rockets, ask whether they have seen or heard of old rocket motors bursting. I have, and they do. I know at Holloman AFB, the sled track guys have squirreled away lots of obsolete rocket motors. It cost hundreds of millions to set up a factory to make new motors, so these guys get what they can, because their customers are cheap. But, once in a while, old rocket motors blow up on the track due to burn rate instability. And there are the stories about old airborne rocket targets that went poof in the launch phase. I saw videos of three sequential tests with Lance missiles as the target, where each Lance blew up in the air, without being intercepted by the customer’s rocket. Interception tests, with all the people, and all the equipment, costs are one million dollars a day at the low end. Major tests, with radars, launchers, etc, tens of millions, and the whole test sequence, hundreds of millions. Got to tell you, when Navy Aegis ships are between Hawaii and California, trying to shoot a Vanderburg missile on the way to Kwajelein, and guys in Alaska are tracking the launch and sending info to the Navy ship and to land based systems, and Kwajelein, hundreds of millions can be spent in one day. Ships are expensive to rent. Airbourne radar planes used to be $75,000 an hour, and you pay from where they took off, and return to. And then there were millions are spent in the planning, transport, of all the equipment for the test. No one is particularly happy when millions in budget, and months of work go poof in the air.

There has been, and is, a lot of study going into the deflagration to detonation transition. There are so many papers behind paywalls, https://www.bing.com/search?q=defla...0F9A2489EA225D58D0D873752&ghsh=0&ghacc=0&ghpl= but overall, given the interest, given the study, its real. Along with the pressure rises that occur when propellants age.

Last edited:

Snowdog

Member

- Joined

- Dec 24, 2002

- Messages

- 4,606

I still have a couple of thousand rounds of FN 7.92x57 dated to 1950 and all the rounds that I've tried through my M48 and M48A work perfectly. It boils down to storage. I have some 8x56R with 1938 headstamp and though I don't want to use much of it (may be a collectible) but they also work well... one hell of a recoil-monster out of a M95 to be certain.

As a comment on "storage is everything"

This was a study conducted in Norway. Except for the humidity, storage conditions are just about ideal. The report states between storage locations, mean storage temperatures varied between 41 °F and 49 °F.

An examination of deterioration of ammunition by storage

https://apps.dtic.mil/sti/citations/ADA055897

S Eriksen and E Stromoe May 1978

Various types of munitions and medium caliber shells were tested for ballistic stability, and after storage periods of 5 and 7 years, there are measurable differences in ballistic performance for munitions stored at different locations. It is unfortunate the Norwegians did not have the newly made ballistics to show how much change had occurred from when the ammunition was new. But they still were able to show differences in performance based on storage locations.

Storage conditions do have a huge influence on the aging of smokeless propellants, hot and humid accelerates deterioration. Cool and dry slow deterioration. It would be hard to find a better place to store ammunition than Norway. And yet, munitions are changing in storage. I was told Antarctica would be ideal as humidity is low and organic things freeze dry. However, no matter how much anyone wants it, nitrocellulose is breaking down from a high energy material to a low energy material. And as it does so, the burn rate changes too.

This was a study conducted in Norway. Except for the humidity, storage conditions are just about ideal. The report states between storage locations, mean storage temperatures varied between 41 °F and 49 °F.

An examination of deterioration of ammunition by storage

https://apps.dtic.mil/sti/citations/ADA055897

S Eriksen and E Stromoe May 1978

Various types of munitions and medium caliber shells were tested for ballistic stability, and after storage periods of 5 and 7 years, there are measurable differences in ballistic performance for munitions stored at different locations. It is unfortunate the Norwegians did not have the newly made ballistics to show how much change had occurred from when the ammunition was new. But they still were able to show differences in performance based on storage locations.

Storage conditions do have a huge influence on the aging of smokeless propellants, hot and humid accelerates deterioration. Cool and dry slow deterioration. It would be hard to find a better place to store ammunition than Norway. And yet, munitions are changing in storage. I was told Antarctica would be ideal as humidity is low and organic things freeze dry. However, no matter how much anyone wants it, nitrocellulose is breaking down from a high energy material to a low energy material. And as it does so, the burn rate changes too.

Similar threads

- Replies

- 2

- Views

- 433

- Replies

- 23

- Views

- 3K