You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Any cool home builds?

- Thread starter Rubber_Duck

- Start date

- Status

-

Not open for further replies.

Alaskan Ironworker

Member

I made this ballista a couple years ago. I think it qualifies as a mad max weapon. Im pretty sure it will kill a moose if one happened to wander in front of it. The bow is made of leaf springs, and the bolts are 1/2” steel conduit. It actually has a pretty nice trigger lol.

Attachments

JeeperCreeper

Member

I actually started working on a "gnarly" Ithaca pump build years ago in college... Ended up breaking the trigger doing slam fires...

Never finished her

Never finished her

earlthegoat2

Member

In the spirit of 80 percent lowers I decided those are too easy, anybody can do those, so I made myself what I call the Mad Max blaster by welding a lower receiver together out of steel plates:

View attachment 867158

Anybody else have any cool or eccentric home builds?

Please tell us more about this wild contraption

Rubber_Duck

Member

The lower was made from laser cut steel plates sold in kit form by the Flat Spot. It was fun, interesting, and a headache at the same time.

The upper is a PSA with a 16-inch barrel and carbine gas system, a combination I absolutely despise for its awkward looks as well as excessive dwell time, so instead of throwing it in the trash this project was born.

The upper has an ugly UTG rail I cut sections off to change the looks of, and a series of washers and an old hole saw welded together for a post-apocalyptic muzzle device. Also some black iron pipe welded to it here and there, combined with the steel lower this thing weighs probably 12 or 14 pounds, so recoil is practically non-existent.

The upper is a PSA with a 16-inch barrel and carbine gas system, a combination I absolutely despise for its awkward looks as well as excessive dwell time, so instead of throwing it in the trash this project was born.

The upper has an ugly UTG rail I cut sections off to change the looks of, and a series of washers and an old hole saw welded together for a post-apocalyptic muzzle device. Also some black iron pipe welded to it here and there, combined with the steel lower this thing weighs probably 12 or 14 pounds, so recoil is practically non-existent.

Last edited:

troy fairweather

Member

I just looked them up quick, I may have to try one this winter.

gotboostvr

Member

Paging @Michael Tinker Pearce

Michael Tinker Pearce

Member

- Joined

- Oct 23, 2016

- Messages

- 1,576

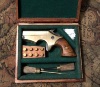

Not as cool as that Mad Max blaster, but I made this rolling-block .22 with a 10/22 barrel last winter. 16-1/4" Barrel, brass receiver and Quilted Maple stocks.

The leftover section of 10/22 barrel became a liner for this little guy. Steel and brass frame, desert ironwood grip- scales. and then the box and tools completed the project.

Demi-human

maybe likes firearms a little bit…

(Proudly struts up with assembled AR. )

(Sees Micheal’s and Rubber duck’s firearms)

Oh! Those are awesome! You made those? From scratch? Dang. That’s cool!

(places Blackout behind back)

Huh? Nothing. Just my, uh, just ‘bout to hit the range. No. Not built, not really, anyway...

And definitely not with Quilted Maple!

(Sees Micheal’s and Rubber duck’s firearms)

Oh! Those are awesome! You made those? From scratch? Dang. That’s cool!

(places Blackout behind back)

Huh? Nothing. Just my, uh, just ‘bout to hit the range. No. Not built, not really, anyway...

And definitely not with Quilted Maple!

The welding required alone might help keep you warm in upstate NY.I just looked them up quick, I may have to try one this winter.

whughett

Member

Duck: That contraption qualifies as a “MaGiver or Rube Goldberg “ device. Take your pick. A freaking hole saw as a flash hider, awesome.

db_tanker

Member

The holesaw is just an awesome touch...I love that...

Rubber_Duck

Member

Thanks guys.

I really like the rolling block .22 and giant crossbow posted in this thread too.

I really like the rolling block .22 and giant crossbow posted in this thread too.

kBob

Member

I believe some M1 carbine trigger housings were built of waffered plates

-kBob

-kBob

tark

Member

I made every gun in these pics from scratch. I made everything but the barrels, the screws and the springs. The longer rolling block is a 45-70, made from 1045 and heated treated to 40 on the C scale. The shorter roller is a 30-06, made from 4140 and also heat treated. It passed proof @ 85,000 PSI. The two blued pistols are a .38 special in the foreground and a 45 P.I.T.A. 45-70 cut down to 1 1/2". The pistol in the white is a 22 Mag.

The 30-06 took seven years to make, an hour here and an hour there, after work .

The 30-06 took seven years to make, an hour here and an hour there, after work .

Attachments

tark

Member

I see my puter is drunk again.sorry about the upside down pic.

OrangeCat

Member

- Joined

- Mar 24, 2019

- Messages

- 407

Okay first of all I think you win prettiest Homebrew second I'll bite how does this little guy lock the barrel in place. It seems like it should be locked by the steel bit of the frame when it's cocked but I'm not quite sure that's actually what's going on.

Edit nope I see the second pin now so that's not what's going on I'm back to stumped.

Last edited:

Michael Tinker Pearce

Member

- Joined

- Oct 23, 2016

- Messages

- 1,576

Okay first of all I think you win prettiest Homebrew second I'll bite how does this little guy lock the barrel in place. It seems like it should be locked by the steel bit of the frame when it's cocked but I'm not quite sure that's actually what's going on.

Edit nope I see the second pin now so that's not what's going on I'm back to stumped.

Thank you! Do you mean how does the breech lock? A projection from the hammer goes under the breech block when the hammer drops, preventing the breech from rotating open.

Shanghai McCoy

Member

Guys, with all the Talent, Skill and Innovation pictured here that "Like" thingie is woefully inadequate.

Well Done Gents.

Well Done Gents.

OrangeCat

Member

- Joined

- Mar 24, 2019

- Messages

- 407

Oh sorry I should have been more specific I meant the tip up barrel on the little pistol.

I kinda get how rolling blocks work in a it's not quite voodoo way

Actually now that you mention it is it the same basic principle but directed to that little notch cut under the barrel liner?

I kinda get how rolling blocks work in a it's not quite voodoo way

Actually now that you mention it is it the same basic principle but directed to that little notch cut under the barrel liner?

Last edited:

Michael Tinker Pearce

Member

- Joined

- Oct 23, 2016

- Messages

- 1,576

Oh sorry I should have been more specific I meant the tip up barrel on the little pistol.

I kinda get how rolling blocks work in a it's not quite voodoo way

Oh! Right, none of the pictures show the lock... there is a manual spring-plunger in the frame that engages a hole in the projection at the bottom of the barrel housing that forms the hinge. Slide the catch to the rear and the barrel can be tipped up.

Mauser lover

Member

I made every gun in these pics from scratch. I made everything but the barrels, the screws and the springs. The longer rolling block is a 45-70, made from 1045 and heated treated to 40 on the C scale. The shorter roller is a 30-06, made from 4140 and also heat treated. It passed proof @ 85,000 PSI. The two blued pistols are a .38 special in the foreground and a 45 P.I.T.A. 45-70 cut down to 1 1/2". The pistol in the white is a 22 Mag.

The 30-06 took seven years to make, an hour here and an hour there, after work .

So... how did you proof the .30-06? I would like to build a falling block or rolling block either this winter or next.

Beautiful, by the way. Does anyone have more pics?

- Status

-

Not open for further replies.

Similar threads

- Replies

- 26

- Views

- 2K

- Replies

- 10

- Views

- 485

- Replies

- 25

- Views

- 2K

![IMG_3351[1].JPG](/data/attachments/810/810249-ceea0076a84b82e8f862f190a930566a.jpg)

![IMG_3339[1].JPG](/data/attachments/810/810250-0e556e1d3393b0b272d329fe1371230e.jpg)

![IMG_3337[1].JPG](/data/attachments/810/810251-067248cbca2f83730280f27c3994d57e.jpg)

![IMG_3341[1].JPG](/data/attachments/810/810252-571c9db4fadde58f052f988378a705ac.jpg)