Does anyone have a program to calculate the pressure increase of a hypothetical bullet setback?

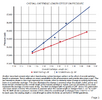

I’m curious about a 45ACP with 185gr XTP, 7 grains Longshot and OAL of 1.230.

Then the pressure increase with the same load .100 shorter at 1.130.

I'm looking for examples a kaboom worthy setbacks. There's lots of free space in a 45ACP so the bullet could sink substantially in the case before contacting powder. I've read that slower powders increase pressure more than fast powders for any given reduction in COAL so I chose Longshot as an example.

I’m curious about a 45ACP with 185gr XTP, 7 grains Longshot and OAL of 1.230.

Then the pressure increase with the same load .100 shorter at 1.130.

I'm looking for examples a kaboom worthy setbacks. There's lots of free space in a 45ACP so the bullet could sink substantially in the case before contacting powder. I've read that slower powders increase pressure more than fast powders for any given reduction in COAL so I chose Longshot as an example.