mmb617

Member

I've only been reloading for a couple years and previously the only bottle neck cases I loaded were .223 for my AR. I have shot several thousand rounds of those without any problems chambering or extracting, and even on cases that were loaded a half dozen times or more I found very few neck splits and I never had any case head separation issues. I load on a single stage Lee press and set up my full length resizing die as directed by Lee, screw it down till it touches the shell holder, then 1/4 to 1/3 turn more. I also anneal my cases after every firing.

A couple months ago I bought a Savage Axis .308 bolt gun and 100 rounds of factory ammo (60 rounds of Aguila 7.62 and 40 rounds of Winchester .308 as that's what was available) since I had no brass. All the factory ammo chambered and extracted without any problems. When I was ready to start reloading I set my FL resizing die up the same way as I did for the .223 and expected similar results.

The first issue I ran into was when some of the reloads would not extract without extreme force on the bolt. I soon realized that it was only the Aguila 7.62 brass that was giving me this problem, the Winchester .308 brass although resized exactly the same way extracted easily. So I set aside the Aguila stuff and bought some once fired Winchester brass. I've since fired several hundred rounds of those reloads without any problems, till yesterday when I got this:

The case didn't completely separate but the crack runs about 3/4 of the way around it. This case had only been fired twice previously so I thought it should have lasted longer than it did. That got me researching the whole case head separation issue and I learned some things about shoulder bump, a subject I'd never even thought about before.

Maybe this case was just a freak as it's the first one I've had with that problem, but it seems like it's something I should be checking. I saw some guys use a bent paper clip to run inside the case to feel if there's a gully forming near the base indicating that case head separation is imminent and I can't feel that in any of the cases I checked, but that's not a real scientific way to check.

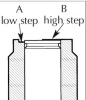

One of the videos I watched on the subject showed a couple different methods for measuring shoulder bump and it seemed to me the Whidden case gauge would be the easiest to use so I ordered one. My understanding is that I can take one of my fire formed cases and measure the shoulder bump on it, then set my resizing die so that it bumps the shoulder back from .001 to .003 more than that measurement. Does that sound right?

I also take it that bumping the shoulder back too far causes premature case head separation issues while not bumping it back enough causes chambering issues. Is that also about right?

One more semi-related question. I've always full length resized my cases but I do have a neck sizing die. Since I only have one rifle chambered in .308 and it's a bolt gun, might I be better served to neck size those cases instead of full length sizing them?

I know that some of my question can be answered by trial and error but I don't see why I should try to reinvent the wheel when I'm sure others already know the answers.

If it matters at all I'm loading what are listed as starting loads with 44 grains of BL-C(2) under a 168 grain HPBT Hornady bullet and a CCI #34 primer.

Anyone who wants to give me their thoughts I'm all ears.

A couple months ago I bought a Savage Axis .308 bolt gun and 100 rounds of factory ammo (60 rounds of Aguila 7.62 and 40 rounds of Winchester .308 as that's what was available) since I had no brass. All the factory ammo chambered and extracted without any problems. When I was ready to start reloading I set my FL resizing die up the same way as I did for the .223 and expected similar results.

The first issue I ran into was when some of the reloads would not extract without extreme force on the bolt. I soon realized that it was only the Aguila 7.62 brass that was giving me this problem, the Winchester .308 brass although resized exactly the same way extracted easily. So I set aside the Aguila stuff and bought some once fired Winchester brass. I've since fired several hundred rounds of those reloads without any problems, till yesterday when I got this:

The case didn't completely separate but the crack runs about 3/4 of the way around it. This case had only been fired twice previously so I thought it should have lasted longer than it did. That got me researching the whole case head separation issue and I learned some things about shoulder bump, a subject I'd never even thought about before.

Maybe this case was just a freak as it's the first one I've had with that problem, but it seems like it's something I should be checking. I saw some guys use a bent paper clip to run inside the case to feel if there's a gully forming near the base indicating that case head separation is imminent and I can't feel that in any of the cases I checked, but that's not a real scientific way to check.

One of the videos I watched on the subject showed a couple different methods for measuring shoulder bump and it seemed to me the Whidden case gauge would be the easiest to use so I ordered one. My understanding is that I can take one of my fire formed cases and measure the shoulder bump on it, then set my resizing die so that it bumps the shoulder back from .001 to .003 more than that measurement. Does that sound right?

I also take it that bumping the shoulder back too far causes premature case head separation issues while not bumping it back enough causes chambering issues. Is that also about right?

One more semi-related question. I've always full length resized my cases but I do have a neck sizing die. Since I only have one rifle chambered in .308 and it's a bolt gun, might I be better served to neck size those cases instead of full length sizing them?

I know that some of my question can be answered by trial and error but I don't see why I should try to reinvent the wheel when I'm sure others already know the answers.

If it matters at all I'm loading what are listed as starting loads with 44 grains of BL-C(2) under a 168 grain HPBT Hornady bullet and a CCI #34 primer.

Anyone who wants to give me their thoughts I'm all ears.