I work on older top break revolvers. Mostly S&W and the pins have rounded ends and should be removed/installed with cup tipped pin punches. Currently I own conventional flat tipped pin punches. Trying to do things right I started looking for cup tipped pin punches and all I can find are sold by Brownells. They do come with a lifetime warranty and go down to approximately 1/16". They certainly aren't inexpensive and at $139 for a set of 8 I'd expect them to last. The overall rating is 3 out of 5 and there are quite a few very negative reviews. Most of the negative reviews reference issues driving tapered pins out of various locations on Sigs. The short pin getting jammed after starting the pin out. There is at least one review indicating that the cups are poorly shaped and the steel is too soft. These would be used mostly on S&W revolvers and maybe some other old firearms. I'll spend the money if these are good for my use. But I've bent my share of pin punches. I just don't want to pay a premium for future bent/broken pin punches.

If used properly is the Brownells cup tipped pin punch set the right set?

www.brownells.com

www.brownells.com

Secondary question - on the older S&W top breaks can someone confirm that the pins are not tapered. I can't measure a difference in diameter but that could be my ability to measure that closely or the fact that the pins I'm measuring are 140 years old.

Third question - assuming the pins are not tapered, I cannot measure a difference in the pin hole diameter from one side to the other. That would mean that a non-tapered pin could be driven out from either side without damage. Is that correct?

The reason I asked the third question is that I currently test each pin in each hole to see what end holds the pin in most securely and what direction that pin works best and always drive that pin in and out based on that information instead of following this rule:

Drive horizontally established pins (and dovetails) out from left to right and reinsert them from right to left. Some modern pins have no taper and then it doesn't matter. For vertically established pins drive them out from below to upwards and to reinsert them drive them from above downwards,

Consider that the pins and holes I'm working with are all over 100 years old and have 100 years of wear. I have resolved that I'll replace all of the pins (and screws) if I decide to re-nickel any of these guns.

If used properly is the Brownells cup tipped pin punch set the right set?

CUP TIP PUNCHES | Brownells

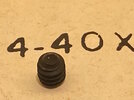

Eight concave “cupped” tip punches to precisely fit the round head pins found on Smith & Wesson handguns. Won’t flatten the pin top and ruin the gun’s looks. Made to the same specs as those used by the factory. Use 3mm punch on SIG handguns. Compl...

Secondary question - on the older S&W top breaks can someone confirm that the pins are not tapered. I can't measure a difference in diameter but that could be my ability to measure that closely or the fact that the pins I'm measuring are 140 years old.

Third question - assuming the pins are not tapered, I cannot measure a difference in the pin hole diameter from one side to the other. That would mean that a non-tapered pin could be driven out from either side without damage. Is that correct?

The reason I asked the third question is that I currently test each pin in each hole to see what end holds the pin in most securely and what direction that pin works best and always drive that pin in and out based on that information instead of following this rule:

Drive horizontally established pins (and dovetails) out from left to right and reinsert them from right to left. Some modern pins have no taper and then it doesn't matter. For vertically established pins drive them out from below to upwards and to reinsert them drive them from above downwards,

Consider that the pins and holes I'm working with are all over 100 years old and have 100 years of wear. I have resolved that I'll replace all of the pins (and screws) if I decide to re-nickel any of these guns.