dennymac, thanks. Yes, I have access to some talented machinists.

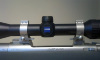

rcmodel in his first post made the comment that maybe I "lapped the rings to large". I've mounted many, many scopes over the last 20 years and have lapped numerous sets of rings (25+) with good success. This is the first time that I've had this issue. I took some photos this morning before I left for work and figured that I'd post them here to show that the rings aren't excessively lapped. You can see in the second photo that the ocular bell is very close to the ring. Eventually it'll make contact which will stop the forward motion but cut into the tube. As mentioned, I'd rather have a conical relief in the back of the rear ring to match the ocular bell so that there's no damage to the tube. I'm a fan of Talley rings and bases and have no intention of looking for any other brand for my hunting rifles. I will check the lapping first though and perhaps more lapping will be all that's needed.

rcmodel in his first post made the comment that maybe I "lapped the rings to large". I've mounted many, many scopes over the last 20 years and have lapped numerous sets of rings (25+) with good success. This is the first time that I've had this issue. I took some photos this morning before I left for work and figured that I'd post them here to show that the rings aren't excessively lapped. You can see in the second photo that the ocular bell is very close to the ring. Eventually it'll make contact which will stop the forward motion but cut into the tube. As mentioned, I'd rather have a conical relief in the back of the rear ring to match the ocular bell so that there's no damage to the tube. I'm a fan of Talley rings and bases and have no intention of looking for any other brand for my hunting rifles. I will check the lapping first though and perhaps more lapping will be all that's needed.