westernrover

Member

- Joined

- May 4, 2018

- Messages

- 1,613

Can I develop a load for a rifle using resized brass and then produce the load with new brass? Should I plan on firing all my new brass? Or should I try to resize the fired brass to match the new brass?

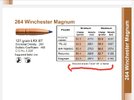

I want to load a couple hundred cartridges for an expensive-to-shoot, short barrel-life magnum. I've bought new Nosler fully-prepped brass - not many other options for this one. I'll be developing a load and using a minimal number of cartridges to do so. I'm only going to use one powder and bullet and try to do it as efficiently as possible. Fortunately, I've got two other rifle/bullet combinations to develop loads for to get my process down before I attempt this one.

Normally, I would have fired brass and bump the shoulder with the FL or body sizing die sufficiently so the bolt-handle drops without resistance on at least 10 different cases and then resize all my cases with that die setting. Typically, I'm bumping 2 or 3 thou.

Thanks for all the replies advising me about bump gauges in my other recent thread. Since the Sinclair insert I need is perpetually out of stock, I think I'll order the Whidden because I like the one-piece design vs. base and inserts.

If I were to bump the minimal amount to get bolt drop on all cases, I don't doubt I could get a good result, but I would probably have more case volume than my new cases and the load wouldn't transfer over to the new unfired brass because the initial combustion space would be less.

What do you think of measuring the new brass with the headspace gauge and then resizing the fired brass to match it?

I measured a case fired in my chamber vs a new case using a socket (tip from Varmintterror). It looks like the new cases' shoulders are 6 to 8 thou farther back than fired (I wasn't able to be more precise with the socket). Do I really want to bump ~7 thou and then load the unfired brass with whatever load I come up with? Or should I plan on firing all my brass and resizing?

I want to load a couple hundred cartridges for an expensive-to-shoot, short barrel-life magnum. I've bought new Nosler fully-prepped brass - not many other options for this one. I'll be developing a load and using a minimal number of cartridges to do so. I'm only going to use one powder and bullet and try to do it as efficiently as possible. Fortunately, I've got two other rifle/bullet combinations to develop loads for to get my process down before I attempt this one.

Normally, I would have fired brass and bump the shoulder with the FL or body sizing die sufficiently so the bolt-handle drops without resistance on at least 10 different cases and then resize all my cases with that die setting. Typically, I'm bumping 2 or 3 thou.

Thanks for all the replies advising me about bump gauges in my other recent thread. Since the Sinclair insert I need is perpetually out of stock, I think I'll order the Whidden because I like the one-piece design vs. base and inserts.

If I were to bump the minimal amount to get bolt drop on all cases, I don't doubt I could get a good result, but I would probably have more case volume than my new cases and the load wouldn't transfer over to the new unfired brass because the initial combustion space would be less.

What do you think of measuring the new brass with the headspace gauge and then resizing the fired brass to match it?

I measured a case fired in my chamber vs a new case using a socket (tip from Varmintterror). It looks like the new cases' shoulders are 6 to 8 thou farther back than fired (I wasn't able to be more precise with the socket). Do I really want to bump ~7 thou and then load the unfired brass with whatever load I come up with? Or should I plan on firing all my brass and resizing?