After seeing these threads about Bubba and his crazy contraptions, I've had to do some soul searching.

https://www.thehighroad.org/index.p...you-have-been-a-godsend.918611/#post-12616778

https://www.thehighroad.org/index.php?threads/gunbuster-head-scratchers.918809/

My name is 21, and I'm ... *gulp* Bubba.

While you judge me, let me offer some backstory. This way at least one head-scratchin' Bubba'd gun will have its story told.

This started as a poor condition Turkish Mauser - barrel was more cratered than pitted, nothing matched, and after test firing it I needed a hammer to unlock the action. It was over priced at $50. Add in new trigger, sear, extractor and some pins from Sarco, and I was still well under $100.

I tried to make modifications that "improved" it without increasing the cost - or requiring real tools - because I was newly married and fiscally challenged. That means replacing some little parts and messing around with the wood. It's pillar bedded with a crisp single stage trigger.

It hid in the back of the closet for a long time until I had the ability to pay a gunsmith to rebarrel it, fit a magazine adaptor from Rhineland Arms, and drill and tap the receiver for scope mounts.

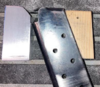

The gunsmith managed to change out the barrel, but he butchered the magazine adaptor and drilling the holes. I built my own magazine adapter from some aluminum square tubing and a piece of stock, but I don't have a machinist's tools. I did this with hand files and sandpaper.

Turns out that getting a rifle action built around a long rifle cartridge to work well with a short fat pistol round is tricky. The heavy bullet tends to fall forward if the extractor hasn't grabbed the rim exactly right, and there's a chasm where the bolt lugs go in front of the chamber.

I had to build a ramp in front of the ramp to get the rifle to feed reliably.

*whew*

I love shooting this messed up baby rifle. The stock has some neat tiger-stripe stuff going on, and mostly doesn't ooze cosmoline anymore

Someday, maybe I'll find a better gunsmith who can build a purpose built bolt action like this, but I am not holding my breath. Until then I've got $500 in the rifle, and it has an estimated resale value of at least $50

https://www.thehighroad.org/index.p...you-have-been-a-godsend.918611/#post-12616778

https://www.thehighroad.org/index.php?threads/gunbuster-head-scratchers.918809/

My name is 21, and I'm ... *gulp* Bubba.

While you judge me, let me offer some backstory. This way at least one head-scratchin' Bubba'd gun will have its story told.

This started as a poor condition Turkish Mauser - barrel was more cratered than pitted, nothing matched, and after test firing it I needed a hammer to unlock the action. It was over priced at $50. Add in new trigger, sear, extractor and some pins from Sarco, and I was still well under $100.

I tried to make modifications that "improved" it without increasing the cost - or requiring real tools - because I was newly married and fiscally challenged. That means replacing some little parts and messing around with the wood. It's pillar bedded with a crisp single stage trigger.

It hid in the back of the closet for a long time until I had the ability to pay a gunsmith to rebarrel it, fit a magazine adaptor from Rhineland Arms, and drill and tap the receiver for scope mounts.

The gunsmith managed to change out the barrel, but he butchered the magazine adaptor and drilling the holes. I built my own magazine adapter from some aluminum square tubing and a piece of stock, but I don't have a machinist's tools. I did this with hand files and sandpaper.

Turns out that getting a rifle action built around a long rifle cartridge to work well with a short fat pistol round is tricky. The heavy bullet tends to fall forward if the extractor hasn't grabbed the rim exactly right, and there's a chasm where the bolt lugs go in front of the chamber.

I had to build a ramp in front of the ramp to get the rifle to feed reliably.

*whew*

I love shooting this messed up baby rifle. The stock has some neat tiger-stripe stuff going on, and mostly doesn't ooze cosmoline anymore

Someday, maybe I'll find a better gunsmith who can build a purpose built bolt action like this, but I am not holding my breath. Until then I've got $500 in the rifle, and it has an estimated resale value of at least $50