Click_Here

Member

- Joined

- Oct 19, 2022

- Messages

- 138

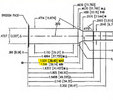

Messing around with the Hornady comparator and I wanted to measure my fired cases compared to factory loaded cartridges.

I measured a few cartridges of 6.5 CM Hornady 140gr ELD M and they were all 1.557

SAAMI Spec on headspace max is 1.551

Whats the deal with that?

My fired cases measure 1.560 bumping it back down -.002 would set me at 1.558 which is also above SAAMI spec.

Who is SAAMI and what does she do? Should I care about her or proceed with what my measurements are telling me?

I measured a few cartridges of 6.5 CM Hornady 140gr ELD M and they were all 1.557

SAAMI Spec on headspace max is 1.551

Whats the deal with that?

My fired cases measure 1.560 bumping it back down -.002 would set me at 1.558 which is also above SAAMI spec.

Who is SAAMI and what does she do? Should I care about her or proceed with what my measurements are telling me?