FastCougar said:

Missouri Bullets IDP #2 SWC 170 gr. .40 S&W bullets ... I've never loaded a straight lead load and was looking for some advice on what a good starting point would be with the Titegroup ... I'm not opposed to getting a different powder, but I'm looking for something that burns cleanly. I figure the bullet lube will produce enough smoke as it is. Also, what OAL should I be shooting for with this bullet?

If you reference the pictures below, Missouri 170 gr SWC (IDP #2) loaded to 1.120" OAL with .421" taper crimp has fed/chambered well in my M&P40/Glock22.

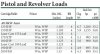

As to load data, I referenced

1999 Winchester load data for W231/HP-38/WSF and

2004 Alliant load data for Promo (As

indicated by Alliant using Red Dot load data by weight).

With slower burn rate powders like WSF, you'll get unburnt powder, dirty burning and decreased accuracy at start-to-mid range load data. With faster burn rate W231/HP-38, you'll get cleaner burn and still accurate loads at start-to-mid range load data.

With W231/HP-38, 4.0-4.5 gr produced fairly clean burning and very accurate loads. With WSF, 5.5-5.8 gr produced cleaner burning and accurate loads. Between the two, I prefer the milder recoil and better accuracy of W231/HP-38 4.0-4.5 gr loads.

With Promo, MBC 180 gr TCFP (IDP #5) was test on this thread -

http://www.thehighroad.org/showthread.php?p=6509911#post6509911

For lighter 170 gr SWC, I plan on testing 3.8/4.0/4.2/4.4/4.5 gr.

180 Lead/3.5 gr - Accuracy all over the 8x11 copy paper - Light recoil

180 Lead/3.8 gr - 7 yard 2" - 10 yard 3" - 15 yard 4" - Mild recoil

180 Lead/4.1 gr - 7 yard 1.5" - 10 yard 1" - 15 yard 4" - Moderate recoil

180 Lead/4.4 gr - 7 yard 1" - 10 yard 2" - 15 yard 2.5" - Firm recoil