flyingtexan86

Member

The GWT 338 LM brass came in a few days ago. Here's my findings so far from the test bench on weights and measurements. I've started load dev so I'll update this post.

I was able to purchase GWT 338 LM brass direct from Go West Trading for $85 / 100pc brass delivered. The gentleman I spoke with offered $0.85 / per each when I mentioned I wanted to test their brass and review it online. He was confident I would find their GWT brass "as good or better" than their competitors and to "expect between 5-20 reloads" per case depending on how I treated the brass. 5-20 is a large gap so we'll see how primer pockets and necks hold up.

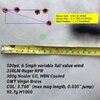

I'm currently working up a load of H1000 pushing HBN coated 300g Nosler CC. Goal is 2800fps and 92g+/- H1000 (This may not be safe in other rifles, so work up!), but pressure and accuracy will be the deciding factor.

Summery:

Sample size was 10 out of 100 cases, virgin brass.

Brass necks had to be chamfered and deburred.

Flash holes had little to no burs.

Brass came annealed and sized (a few out the 100pc required their necks to be resized with an expander ball).

H2O capacity is 114.5g from a fired case out of a Ruger RPR 338LM.

Details:

Case Weight

AVE.......LOW......HIGH.....ES.....SD

320.62...318.30...322.70...4.40...1.517

318.3

318.9

319.3

320.3

320.3

320.5

321.3

322.3

322.3

322.7

Case Length (very consistent)

AVE.......LOW......HIGH.....ES..........SD

2.712.....2.712.....2.7135....0.0015...0.0006

2.712

2.712

2.712

2.712

2.7125

2.7125

2.713

2.713

2.713

2.7135

Neck Thickness (Measurement was taken after hand deburring / chamfer but before tumbling in stainless steel media. Necks grew ave +0.002" after tumbling)

AVE.......LOW......HIGH.....ES..........SD

0.0128...0.0120...0.0135...0.0015....0.0004

0.012

0.0125

0.0125

0.0125

0.0125

0.013

0.013

0.013

0.013

0.0135

Primer pocket depth (measuring was finicky with my 8" calipers as I got different measurements depending on how much pressure I applied, so take these measurements with a grain of salt)

AVE.......LOW......HIGH.....ES.........SD

0.1324...0.1280...0.1340...0.0060...0.0018

0.128

0.131

0.1315

0.133

0.133

0.133

0.1335

0.1335

0.1335

0.134

Primer pocket width

AVE.......LOW......HIGH.....ES.........SD

0.2091...0.2085...0.2095...0.0010...0.0003

0.2085

0.209

0.209

0.209

0.209

0.209

0.209

0.209

0.2095

0.2095

I was able to purchase GWT 338 LM brass direct from Go West Trading for $85 / 100pc brass delivered. The gentleman I spoke with offered $0.85 / per each when I mentioned I wanted to test their brass and review it online. He was confident I would find their GWT brass "as good or better" than their competitors and to "expect between 5-20 reloads" per case depending on how I treated the brass. 5-20 is a large gap so we'll see how primer pockets and necks hold up.

I'm currently working up a load of H1000 pushing HBN coated 300g Nosler CC. Goal is 2800fps and 92g+/- H1000 (This may not be safe in other rifles, so work up!), but pressure and accuracy will be the deciding factor.

Summery:

Sample size was 10 out of 100 cases, virgin brass.

Brass necks had to be chamfered and deburred.

Flash holes had little to no burs.

Brass came annealed and sized (a few out the 100pc required their necks to be resized with an expander ball).

H2O capacity is 114.5g from a fired case out of a Ruger RPR 338LM.

Details:

Case Weight

AVE.......LOW......HIGH.....ES.....SD

320.62...318.30...322.70...4.40...1.517

318.3

318.9

319.3

320.3

320.3

320.5

321.3

322.3

322.3

322.7

Case Length (very consistent)

AVE.......LOW......HIGH.....ES..........SD

2.712.....2.712.....2.7135....0.0015...0.0006

2.712

2.712

2.712

2.712

2.7125

2.7125

2.713

2.713

2.713

2.7135

Neck Thickness (Measurement was taken after hand deburring / chamfer but before tumbling in stainless steel media. Necks grew ave +0.002" after tumbling)

AVE.......LOW......HIGH.....ES..........SD

0.0128...0.0120...0.0135...0.0015....0.0004

0.012

0.0125

0.0125

0.0125

0.0125

0.013

0.013

0.013

0.013

0.0135

Primer pocket depth (measuring was finicky with my 8" calipers as I got different measurements depending on how much pressure I applied, so take these measurements with a grain of salt)

AVE.......LOW......HIGH.....ES.........SD

0.1324...0.1280...0.1340...0.0060...0.0018

0.128

0.131

0.1315

0.133

0.133

0.133

0.1335

0.1335

0.1335

0.134

Primer pocket width

AVE.......LOW......HIGH.....ES.........SD

0.2091...0.2085...0.2095...0.0010...0.0003

0.2085

0.209

0.209

0.209

0.209

0.209

0.209

0.209

0.2095

0.2095

Last edited: