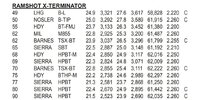

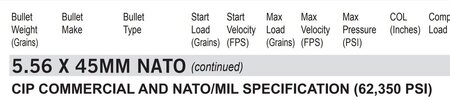

So it looks like the answer is that I am not loading the X-Terminator up to the same MAP as I am loading the Benchmark, H-335, and StaBALL Match. Loading it to a lower peak pressure is resulting in less area under the pressure/time curve or less impulse and therefore less muzzle velocity. The solution is to load it up with a higher charge mass. Then I can compare it to the other powders more fairly.

It was important that before I decided to write it off as a bad combination that I understood why it was not working as expected. It wasn't because it was too slow a powder, or too fast a powder, but because I wasn't loading it up enough -- enough to compare it to the other powders that I was loading at higher pressure. With this understanding, I can compare the powders at similar pressures, and I probably won't have to dismiss X-Terminator for having poor performance in velocity.

As for accuracy, I am testing that, but this thread wasn't about it. All the shots that I obtained velocity from were shot onto targets and the groups measured. My charge/velocity ladders consisted of only two shots per charge mass. I subsequently did not evaluate X-Terminator for 5-shot group size because I was not achieving sufficient velocity for it to matter. The other powders I did.

There is a lot of misunderstanding of what I am trying to do or what my question was in this thread. I've made some errors myself in finding, reading, or interpreting the available data, but never was I trying to achieve listed velocities with a shorter barrel, nor was I trying to maximize velocity.

Some asked the purpose, which is fair. My primary purpose is to evaluate powders and develop my method for evaluating powders. Then I will apply what I hope to be sound methods to evaluating powders for a different bullet, the 55 grain CX. For the CX, velocity and terminal performance will matter as well as accuracy. Why not start with the CX? It should be obvious that I'm figuring out what I'm doing and it's more affordable to do that with the SP. For the SP, it's terminal performance is relevant for one of my purposes, but it is also inexpensive enough to plink with. Loads with insufficient velocity for good terminal performance are less valuable. As I wrote above, I am evaluating accuracy also.