A fellow on the Rem 1858 forum has created a BP HP bullet and has/will create a ram with a HP pin to preserve the integrity of the cavity upon loading. I’ve been wanting to modify my current designs as I see their preferred powder charges don’t change despite projectiles used so I figure instead of fillers I’d fill the excess with lead.

I like a wide meplat as these will penetrate and still create a large wound, which is something I’d want for things like hogs. But I’ve figured a HP version might well be good too (I’d buy an additional loading lever assembly).

What comes to mind is the old Flying Ashtray of Speer. These bullets performed quite well well before these premium offerings we see today. So I’m thinking I’d want to create something along those lines. I know the cavity was wide and deep, but I see differing ideas of what the cavity itself looked like. Some seem to claim it was a straight walled cavity whereas others seem to show the more typical tapered cavity. Without a jacket I’m wondering how thick I’d want/need the initially lip to be. Seems you wouldn’t want it really thin. Right now my meplats run 0.375” on a .452” (after its run through the barrel) bullet. The main bullet weighs 195 grns but with modifications I’m assuming it’ll be somewhere between 205 and 220 grns as a solid and maybe as low as 180 with a huge cavity, if I go that route. I don’t necessarily want to give up too much penetration, though I figure what works on a man will work on a deer well enough, especially as ours are rather small.

I intend to allow for a cereal box cardboard over powder card, another ~1/16” for powder charge variation, and ~1/16” under the chamber mouth as it’s been shown bullets get gas cutting.

I intend to go back to Accurate Molds and send it from there to Hollow Point Molds (?).

Thoughts? Ideas? Recommendations? Anything else to consider?

This is my 195 grn bullet:

http://accuratemolds.com/bullet_detail.php?bullet=45-195C-D.png

I’m likely going to ream my chambers again from 0.449” to maybe 0.452” as my grooves are just slightly over 0.452” on my Pietta NMA. Bullets don’t need to be grossly oversized as with a ball so I’ll reduce the diameter from 0.456” to 0.453-4”. I also want to increase the length and diameter of the base to help keep the bullet centered upon loading and help put some more mass into the chamber reducing the OAL of what’s protruding (I already had to modify the loading window even for my shorter 170 grn version at 0.400”).

Since the chamber walls will be that much thinner after reaming again, as well as increasing the mass, I think it prudent to decrease the top driving band length. I’ve used a weighed 33 grns of 3F Olde E, though I broke that measure and will be reconfiguring the accurate charge, so pressures aren’t higher than with what’s common.

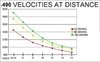

I’ve also debated reducing the meplat from ~83% to 78-80% as some feel above 78% and it can create aerodynamic issues at longer range and I feel the itch for a Remington carbine. But then others claim this is false, and we see plenty of long range handgun hunters using very wide meplats successfully.

Side note for reference:

From what little chronographed results that I’ve found my charge and bullet are within the .45 ACP realm of 350-425 ft/lbs. Some claim it could be a little higher.

I like a wide meplat as these will penetrate and still create a large wound, which is something I’d want for things like hogs. But I’ve figured a HP version might well be good too (I’d buy an additional loading lever assembly).

What comes to mind is the old Flying Ashtray of Speer. These bullets performed quite well well before these premium offerings we see today. So I’m thinking I’d want to create something along those lines. I know the cavity was wide and deep, but I see differing ideas of what the cavity itself looked like. Some seem to claim it was a straight walled cavity whereas others seem to show the more typical tapered cavity. Without a jacket I’m wondering how thick I’d want/need the initially lip to be. Seems you wouldn’t want it really thin. Right now my meplats run 0.375” on a .452” (after its run through the barrel) bullet. The main bullet weighs 195 grns but with modifications I’m assuming it’ll be somewhere between 205 and 220 grns as a solid and maybe as low as 180 with a huge cavity, if I go that route. I don’t necessarily want to give up too much penetration, though I figure what works on a man will work on a deer well enough, especially as ours are rather small.

I intend to allow for a cereal box cardboard over powder card, another ~1/16” for powder charge variation, and ~1/16” under the chamber mouth as it’s been shown bullets get gas cutting.

I intend to go back to Accurate Molds and send it from there to Hollow Point Molds (?).

Thoughts? Ideas? Recommendations? Anything else to consider?

This is my 195 grn bullet:

http://accuratemolds.com/bullet_detail.php?bullet=45-195C-D.png

I’m likely going to ream my chambers again from 0.449” to maybe 0.452” as my grooves are just slightly over 0.452” on my Pietta NMA. Bullets don’t need to be grossly oversized as with a ball so I’ll reduce the diameter from 0.456” to 0.453-4”. I also want to increase the length and diameter of the base to help keep the bullet centered upon loading and help put some more mass into the chamber reducing the OAL of what’s protruding (I already had to modify the loading window even for my shorter 170 grn version at 0.400”).

Since the chamber walls will be that much thinner after reaming again, as well as increasing the mass, I think it prudent to decrease the top driving band length. I’ve used a weighed 33 grns of 3F Olde E, though I broke that measure and will be reconfiguring the accurate charge, so pressures aren’t higher than with what’s common.

I’ve also debated reducing the meplat from ~83% to 78-80% as some feel above 78% and it can create aerodynamic issues at longer range and I feel the itch for a Remington carbine. But then others claim this is false, and we see plenty of long range handgun hunters using very wide meplats successfully.

Side note for reference:

From what little chronographed results that I’ve found my charge and bullet are within the .45 ACP realm of 350-425 ft/lbs. Some claim it could be a little higher.

Last edited:

But I think the 290 and 325 are more for .454 Casull than for .45 Colt. What's really really nice is that GT will swage them down to you size of choice from .452, .453, or .454, so you can pick how much friction you particular barrel is going to encounter balanced with the accuracy that you get...and they will even sell them to you unswaged for size. I think the 225grain would be what one would want.

But I think the 290 and 325 are more for .454 Casull than for .45 Colt. What's really really nice is that GT will swage them down to you size of choice from .452, .453, or .454, so you can pick how much friction you particular barrel is going to encounter balanced with the accuracy that you get...and they will even sell them to you unswaged for size. I think the 225grain would be what one would want.