I have loaded different brands of plated bullets over the years with no problems. I bought some different .45 bullets once not long ago and even though I had used bullets of the same brand before I had shaving issues this time. I had to adjust the expander a bit and that solved the problem. Maybe your expander can't get the bell quite enough for these.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Problems with the 45 Auto

- Thread starter ArchAngelCD

- Start date

- Status

-

Not open for further replies.

ArchAngelCD

Member.

That's what I am saying, I think my die won't expand the neck enough to prevent the problem but only with these bullets. I welcome the opportunity to see if it's this batch of bullets or my die. (or even me)I have loaded different brands of plated bullets over the years with no problems. I bought some different .45 bullets once not long ago and even though I had used bullets of the same brand before I had shaving issues this time. I had to adjust the expander a bit and that solved the problem. Maybe your expander can't get the bell quite enough for these.

LiveLife

Member

OK, got the Berry's 185 gr HBRN bullets from ArchAngelCD.bds said:ArchAngelCD is going to send me some of the bullets.ArchAngelCD said:Lee die for the 45 Auto not flaring the neck enough not to shave the cover off a plated bullet

If I experience the same problem of plating shaving with my Lee dies then the bullets will be suspect.

If I do not experience the same problem then problem would be something else.

- I initially measured all the bullets for out-of-round and they consistently measured .452" at several different places. These are very round bullets and we can rule out out-of-round bullets causing the shaving of plating.

- C-H 205 single stage press with Lee carbide die set (same brand as OP) were used and bullets were seated/taper crimped in the same step

- Unmodified brass (case mouth not chamfered) with BLAZER/FEDERAL/WIN/SPEER headstamp were used along with once-fired BLAZER brass with sharp case mouth edges

- After full-length resizing, case mouths measured around .467" - .468" at several places on the same case so the cases were relatively round after being resized

- Case wall measurements ranged .011" - .012" with most of measurements at .011"

- Case mouths were flared to about .472" which allowed the .452" sized bullets to just barely sit on the case mouth without tilting

- .471" taper crimp and 1.255" - 1.260" OAL/COL were used

Findings:

I did not experience shaving of plating. I even intentionally allowed a couple of the bullets to tilt when set on the case mouth and they were seated/taper crimped without shaving the plating.

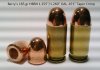

The picture below is a representation of the test rounds loaded

Attachments

ArchAngelCD

Member.

OK then, it is not the bullets so it's either a die that will not expand the neck enough or more probably something I'm doing wrong. I guess it doesn't matter how many years you are reloading, you can still do something wrong.

Bds, thank you very much Sir for loading and checking those bullets. I do appreciate your time and effort.

Bds, thank you very much Sir for loading and checking those bullets. I do appreciate your time and effort.

LiveLife

Member

Since we know it's not the bullets, if you are shaving the plating only on a few cases, we could probably rule out the expander also but I would check the average flare amount to be at least .472".

I would next check the variables that could cause shaving of plating on some of the cases - tilting of case and/or bullet during seating along with case wall thickness.

- Inspect the case rim for damage. Perhaps worn/damaged case rim may not be allowing the case to sit straight and slightly tilting the case to cut into the bullet.

- Inspect the inside of the case neck for obstruction. If not clean/smooth and the bullet is not set straight, the bullet could be seated tilted causing the shaving of the plating.

- Case wall thickness could vary by head stamp and lot-to-lot. Cases I used had fairly consistent thickness (.011"-.012"). While thicker walled cases will receive the same amount of expanding from the expander (ID) but will cut into the bullet/plating deeper with the same amount of taper crimp (OD). Pull apart the shaved rounds and measure the case wall thickness to see if they are thicker.

If none of these variables are the reason for shaving of plating, then it's something else.

I would next check the variables that could cause shaving of plating on some of the cases - tilting of case and/or bullet during seating along with case wall thickness.

- Inspect the case rim for damage. Perhaps worn/damaged case rim may not be allowing the case to sit straight and slightly tilting the case to cut into the bullet.

- Inspect the inside of the case neck for obstruction. If not clean/smooth and the bullet is not set straight, the bullet could be seated tilted causing the shaving of the plating.

- Case wall thickness could vary by head stamp and lot-to-lot. Cases I used had fairly consistent thickness (.011"-.012"). While thicker walled cases will receive the same amount of expanding from the expander (ID) but will cut into the bullet/plating deeper with the same amount of taper crimp (OD). Pull apart the shaved rounds and measure the case wall thickness to see if they are thicker.

If none of these variables are the reason for shaving of plating, then it's something else.

243winxb

Member

Post 6, seating die problem.

LiveLife

Member

243winxb, the OP is using Lee dies and not RCBS dies. I also have Dillon/RCBS dies but I don't think me testing with Dillon/RCBS dies would duplicate OP's situation with Lee dies.

That's why I had the OP send me some of the bullets to verify whether the shaving of the plating was due to the bullets, Lee dies or something else.

Since I could not duplicate the problem, I don't think the issue is with the bullets. Since I also used Lee dies, I don't think the issue is die related. I posted the flare measurements to set consistency for OP to retest.

I believe OP is not shaving plating all the time. Also, I think OP posted same brand/type of bullet was used in the past without the shaving issue.

So I think shaving of the plating is due to variables that may have changed for the OP. If bullets and dies are not the reason, then it's something else.

That's why I had the OP send me some of the bullets to verify whether the shaving of the plating was due to the bullets, Lee dies or something else.

Since I could not duplicate the problem, I don't think the issue is with the bullets. Since I also used Lee dies, I don't think the issue is die related. I posted the flare measurements to set consistency for OP to retest.

I believe OP is not shaving plating all the time. Also, I think OP posted same brand/type of bullet was used in the past without the shaving issue.

So I think shaving of the plating is due to variables that may have changed for the OP. If bullets and dies are not the reason, then it's something else.

243winxb

Member

The inside diameter of the seating die, if to small , doesnt matter what brand. If it starts removing the flare to soon , bullets gets shaved.

I have been using the Lyman M step expander with all my Lee die sets for all pistol calibers since about 1990. It IS a better idea. Bullets will easily snap into the case and sit straight when seating and it cannot overwork the case mouth. Cases last pretty much forever. You can buy the die for one caliber or a die with threaded inserts for 5 different calibers. Try one.

LiveLife

Member

243winxb, I agree with your premise but the OP has been reloading with the SAME die set for a long time without issues (they are 10 years old). BTW, I have 3 Lee die sets with one 20+ years old and others about 5-10+ years old.

I believe the OP's question was WHY NOW?

And we are trying to determine why the OP is NOW shaving plating when this was not an issue before. So my approach to determining the "root cause" was:

- Bullets with defective/thin plating - Checked

- Out-of-round bullets - Checked

- Lee Powder Thru Expander - Checked with .472" flare

- Taper crimp - Checked with .471" taper crimp (seat/crimp in one step same as OP)

- Tilting bullets - Checked with small sample of 2 bullets

I suggested OP retest using .472"+ flare and checking case rim/neck for damage/wear/obstruction.

ArchAngelCD, if I am off on my assessment let me know.

Keep us posted as I am sure many are curious, me included.

I believe the OP's question was WHY NOW?

And we are trying to determine why the OP is NOW shaving plating when this was not an issue before. So my approach to determining the "root cause" was:

- Bullets with defective/thin plating - Checked

- Out-of-round bullets - Checked

- Lee Powder Thru Expander - Checked with .472" flare

- Taper crimp - Checked with .471" taper crimp (seat/crimp in one step same as OP)

- Tilting bullets - Checked with small sample of 2 bullets

I suggested OP retest using .472"+ flare and checking case rim/neck for damage/wear/obstruction.

ArchAngelCD, if I am off on my assessment let me know.

Keep us posted as I am sure many are curious, me included.

LiveLife

Member

I love the replies to threads where solution to "Red" press is a "Blue" press

While I admire the attributes of the Lyman M die, I actually would lean towards using the NOE Powder Thru Expander BECAUSE I CAN CONTINUE TO USE MY LEE POWDER MEASURES - http://noebulletmolds.com/NV/index.php?cPath=91

So for users of 3 station Pro 1000, Lyman M die is not a viable solution while NOE Powder Thru Expander plug is.

While I admire the attributes of the Lyman M die, I actually would lean towards using the NOE Powder Thru Expander BECAUSE I CAN CONTINUE TO USE MY LEE POWDER MEASURES - http://noebulletmolds.com/NV/index.php?cPath=91

So for users of 3 station Pro 1000, Lyman M die is not a viable solution while NOE Powder Thru Expander plug is.

I have expander dies; I have an RCBS green box assortment of expanders. I have expanders from a long range of expanders that have been made by RCBS. I have expanders that are too large in diameter that that can be modified to fit anything. All I have to be able to do is measure the diameter of the bullet and the diameter of the expanded case neck. There was the one time I could not get the case into the seating die because the case had too much flair.

F. Guffey

F. Guffey

I checked the alignment between the case and die. I am not timid about expanding the neck, if I was I would have to secure the die in the press and make sure it was centered. Some reloaders use the floating to align and self centering: I don’t, I secure the die to the press with the lock nut.

F. Guffey

F. Guffey

LiveLife

Member

But have you had issues with Lee dies and Berry's 185 gr HBRN plated bullet shaving plating?

243winxb

Member

Case wall thickness + tight die.??

Tight die and wall thickness difference.

Tight die and wall thickness difference.

my last guess.Case wall thickness could vary by head stamp and lot-to-lot. Cases I used had fairly consistent thickness (.011"-.012"). While thicker walled cases will receive the same amount of expanding from the expander (ID) but will cut into the bullet/plating deeper with the same amount of taper crimp (OD). Pull apart the shaved rounds and measure the case wall thickness to see if they are thicker.

kerreckt

Member

I have never experienced the problem you describe, with 45 acp. I have used Lee dies with plated bullets, and others, and have not had any "shaving". The dies I have could put (and have accidently) enough bell to ruin the case.

ArchAngelCD

Member.

No bds, you are not getting anything wrong. The dies are 10+ years old and no problems before and I use a lot of lead bullets. I have loaded plated bullets before, just not those bullets. It does not happen with all these 185gr bullets but does with a majority of them. Originally I did measure the flare applied by my die but I can't find those notes so I will have to check the numbers again. This is probably a moot point since I won't be buying these bullets again but that's not a knock on the bullets or company.

LiveLife

Member

Thanks for the clarification. So I gather you did not shave the lead bullets sized .452"?ArchAngelCD said:The dies are 10+ years old and no problems before and I use a lot of lead bullets. I have loaded plated bullets before, just not those bullets. It does not happen with all these 185gr bullets but does with a majority of them.

While I really like Berry's 9mm HBRN bullets for accuracy they produce, with the 185 gr 45ACP HBRN bullets, I think the hollow cavity inside the bullet is so large that at typical 1.250"-1.260" OAL, my load behaves like a solid base bullet loaded really long and I needed to use more powder than my 200 gr loads or I got unburnt powder granules.This is probably a moot point since I won't be buying these bullets again but that's not a knock on the bullets or company.

Now I am leaning more towards 200 gr RN plated bullets over the 185 gr HBRN. Berry's does make 200 gr HBFP and RSFP bullets so I plan to test them when I get a chance (Interestingly, Berry's website shows smaller cavity for 200 gr HBFP bullet).

So far this winter, El Niño rain storms have hit the west coast hard and effectively cancelled my plan of load development/chrono testing during my December/January time off (wife did let me clean the inside of the house really well.

ArchAngelCD

Member.

You know, come to think of it I do get some shaving with lead bullets but I just wipe it away with a cloth not really thinking about it. I guess that's because it doesn't make as big of an impression as plating on the outside of the case lol. Funny thing is, those plated bullets what didn't load right shot just fine, go figure...

LiveLife

Member

When I am seating and taper crimping lead bullets in one step, I keep the OAL the same but incrementally decrease the taper crimp until I start shaving the bullet and back off until I don't.

Occasional thicker walled cases will shave a sliver of lead but like you, I wipe it off with a paper towel.

I have the Dillon 650 set up for 45ACP with separate seat and crimp but gotten spoiled by the dedicated Pro 1000 set up that when using jacketed/plated bullets, I often find myself using the Pro 1000. When I start casting and powder coating bullets, I will probably use the 650 more.

Occasional thicker walled cases will shave a sliver of lead but like you, I wipe it off with a paper towel.

I have the Dillon 650 set up for 45ACP with separate seat and crimp but gotten spoiled by the dedicated Pro 1000 set up that when using jacketed/plated bullets, I often find myself using the Pro 1000. When I start casting and powder coating bullets, I will probably use the 650 more.

LiveLife

Member

The testing I did for the OP was mainly to rule out the bullet and the die/expander factors.

I used mixed range brass along with known once-fired brass and measured the case mouth flare of all the test cases.

If any one of the cases was short, I figured it would show up as smaller amount of flare on case mouth. All the case mouths were flared to .472"+ for me to rule out not using enough flare to cause the shaving of the plating.

OP could pull the shaved rounds and measure the resized case lengths to see if the offending cases are short. If they are, they could end up with less flared case mouths which would attribute to the shaving of plating.

I used mixed range brass along with known once-fired brass and measured the case mouth flare of all the test cases.

If any one of the cases was short, I figured it would show up as smaller amount of flare on case mouth. All the case mouths were flared to .472"+ for me to rule out not using enough flare to cause the shaving of the plating.

OP could pull the shaved rounds and measure the resized case lengths to see if the offending cases are short. If they are, they could end up with less flared case mouths which would attribute to the shaving of plating.

ArchAngelCD

Member.

I cleaned all the 45 dies when this first happened but the weren't dirty. I am seating and taper crimping in separate steps. The plating is being compromised at the very beginning of the seating process.

- Status

-

Not open for further replies.

Similar threads

- Locked

- Replies

- 54

- Views

- 6K

- Replies

- 18

- Views

- 628

- Replies

- 3

- Views

- 661