makos_goods

Member

Uhhhhhhhh, first of all what do you have that has Ø.357 chambers?I have a question for those of you that "swage," if it doesn't shave lead how do you know if it has fully engaged the walls?

Because the balls I use measure .360 dia. and the walls in the chambers measure .357

The .003 has to go somewhere.

Secondly, if you do have Ø.357 chamber and if you extract your ball using pressure through the flash hole you will measure it smaller than Ø.3570. You don't have to believe me, just try it, you'll be amazed.

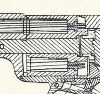

The difference (whatever it is you have in your case) is squeezed down with space between the ball and the chamber diameter. The space is occupied with whatever was at the swaging interface between the ball and the bore. It might be grease, lube, fouling or even smeared lead which acts as a boundary film.

If you buy swaging tools they will ask you several things, materials, material condition, lubricant to be used, etc. You don't call them up and say "hey I need a XXX diameter die." You call them up and say, "hey I need the material to be XXX diameter after forming."

If you measure the die using precision tooling you will find it is larger in diameter that the finished part.

The reason the cut surface doesn't get smaller is that you didn't have the displacing forces compressing the ball on the diameter. Instead you had shearing loads which relieves the pressure and allows a full ring contact patch around the periphery.

You can demonstrate that as well, by blowing a ball back out of the chamber. Be careful and stop it literally a full diameter away as it leaves the bore. Pop it into some modeling clay. Compare the contact patch between the two and you will find two things. The cut patch is wider and also larger in diameter and it will have a torn or cut looking surface as compared to a burnished and slicker surface the swaged ball will have.

Regards,

Mako