I know it's a mouse, but it's still a lot of fun to shoot. I started reloading the .380 some time ago and ran into a problem. I put 2.7-2.9 grains of bullseye behind a 95 grain FMJ. Due to the case wall thickness, (or thin-ness) the case will bulge if the bullet is not near perfectly columned during the seating process. I roll the bullet in case lube to minimize friction. Anyone have a silver bullet (pun) for this problem?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Reloading the .380 ACP

- Thread starter Sky Dog

- Start date

- Status

-

Not open for further replies.

Different headstamps have a different inside case taper. You may be running into this.

I only load cast. When I get a bulging case I run them into a .233 sizing die with the decapping/expanding plug removed. Not all the way in, just enough to smooth them out. Not sure how this would work with FMJ.

I only load cast. When I get a bulging case I run them into a .233 sizing die with the decapping/expanding plug removed. Not all the way in, just enough to smooth them out. Not sure how this would work with FMJ.

LiveLife

Member

I use 95 gr Montana Gold JHP and 100 gr X-Treme RNFP plated bullet for Taurus 738 TCP using W231/HP-38 with this mod - http://www.thehighroad.org/showthread.php?p=9318202

No bullet seating issues for me using Lee carbide dies and mixed range brass and minimal case neck flare (just enough to set the bullet).

I would not use any lube on the bullet with the concern for reducing neck tension. With both bullets and mixed range brass, I get no bullet setback when fed/chambered from the magazine.

No bullet seating issues for me using Lee carbide dies and mixed range brass and minimal case neck flare (just enough to set the bullet).

I would not use any lube on the bullet with the concern for reducing neck tension. With both bullets and mixed range brass, I get no bullet setback when fed/chambered from the magazine.

I use the LEE FCD. Boo, Hiss It's junk etc.

But my ammo works. I used to collect 380 Mouse guns and shot many, many rounds, lead, FMJ and JHP.

My Sig and CZ (and others) are tack drivers so folks can say what the want about the LFCD

But my ammo works. I used to collect 380 Mouse guns and shot many, many rounds, lead, FMJ and JHP.

My Sig and CZ (and others) are tack drivers so folks can say what the want about the LFCD

LiveLife

Member

Use of FCD with jacketed diameter bullets to "fix" out of round/spec bullets so they will fit in SAAMI max chambers is what the FCD was originally intended for. And yes, I have come across some out of round plated bullets (and that's why they are double-struck).

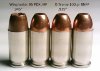

Jacketed bullets (FMJ/JHP) can tilt during seating and cause bulging more on one side, which I think may be the OP's problem.

While I normally do not use FCD for my reloading, I have used them before to "fix" out of round batch of bullets.

Jacketed bullets (FMJ/JHP) can tilt during seating and cause bulging more on one side, which I think may be the OP's problem.

While I normally do not use FCD for my reloading, I have used them before to "fix" out of round batch of bullets.

Jesse Heywood

Member

bds said:No bullet seating issues for me using Lee carbide dies and mixed range brass and minimal case neck flare (just enough to set the bullet).

I'm in the same camp with BDS, only I load both lead and jackets. I use RCBS dies and have no issues with the wall bending. My only problem is when brass has a ridge inside the case for bullet seating. If the bullets I'm using don't work with the case, they go in a stack to load with other cases.

I use a Lee 105 grain mold and X grains of red dot and RCBS dies and mixed head stamp brass and always a roll crimp and never have had the problem that you are having so you must be doing something wrong. Maybe you are not using enough flare on the case to seat the bullet easily. I use just a little bit of flare just enough to catch my fingernail down the case.

kerreckt

Member

I haven't come across this problem too often but when I do I drink FCD. lol. I mean I use the good ole' FCD and problem gone.

rcmodel

Member in memoriam

OhMy!I roll the bullet in case lube to minimize friction. Anyone have a silver bullet (pun) for this problem?

Don't do that!

Case neck friction is all that prevents bullet set-back during feeding.

Lubing the bullet to reduce it is a very bad idea.

rc

No, lubing a bullet will not change its diameter if out of spec. Seems likely that a little bullet bulge is normal. It is for my loading of Rainier plated bullets in .380. I get a little bulge but typical. Remember you are sizing your cases down, flaring the mouth for seating, and then inserting a bullet - some case bulge is going to happen. I wouldn't think that using a .223 die is good either. Why not just use your Lee dies to seat the bullet and then crimp (remove the bell) in two separate operations? I like the .380 as well. It is a good cartridge. I'll shoot the typical magnum handguns as well, but the .380 is pleasant to shoot and easy to shoot well.

Schwing

Member

Question on this: Does it really matter if a few get that little bulge? I have separated out some of mine that have done this and shot them separately. I have never been able to tell the difference in accuracy or function.

Take the ones you feel have a more pronounced bulge and drop them into the chamber. Do they seem to fit just like the ones without the bulge? Also, are your calipers measuring a substantial difference at the bulge area? Grant you in .380 it does seem that precise bullet alignment during bullet seating can be challenging but not insurmountable. If the rounds chamber and shoot fine then don't worry to much about it.

Potatohead

Member

- Joined

- Mar 9, 2013

- Messages

- 5,375

I've had a lot of trouble loading 380. So much that Ive given up momentarily. Cannot for the life of me get enough neck tension to hold a bullet in place..about every other round fails the push test.

Jesse Heywood

Member

Potatohead - What bullets are you loading? If they are the correct size, lead .356 jacket .355, your expander could be too large.

Vodoun da Vinci

Member

Have not done any .380 yet but I have had the problem with .32 ACP. On some brass that has thick walls the bullets will bulge the case a little more and make them look unsightly. As long as they chamber it's not a big deal and yes getting them seated square is really important to avoid making it worse.

Resist temptation to open the mouth of the case wider or use lube for the reason already mentioned. I have CH4D .32 dies and a separate taper crimp die which just takes the bell off the case. Resist the urge to squish/taper crimp it to get rid of the bulge as that only makes more problems.

VooDoo

Resist temptation to open the mouth of the case wider or use lube for the reason already mentioned. I have CH4D .32 dies and a separate taper crimp die which just takes the bell off the case. Resist the urge to squish/taper crimp it to get rid of the bulge as that only makes more problems.

VooDoo

LiveLife

Member

I think BDS has the right idea. I just resized 1000 cases. I have some Remington Golden Sabre's to try. That will eliminate any tilting problems.

As long as they chamber, I've had no problems. I'm very happy with the accuracy in my Sig 230 and my Beretta Cheetah.

As long as they chamber, I've had no problems. I'm very happy with the accuracy in my Sig 230 and my Beretta Cheetah.

- Status

-

Not open for further replies.

Similar threads

- Replies

- 39

- Views

- 2K

- Replies

- 25

- Views

- 984

- Replies

- 39

- Views

- 5K