S&W introduced the full moon clip in 1917 along with the half moon clip. The full moon clip was a complicated affair with springs and it was decided by the Army to utilize the 1/2 moon instead. Much simpler, it stored easier, it packed easier, it shipped easier.

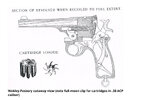

Here is the patent for the full moon clip.

View attachment 1179134

Two ways of packing the loaded half moon clips,

View attachment 1179131

View attachment 1179132

And the machine used to load the half moon clips,

View attachment 1179133

I have never seen one of the original full moon clips, nor a photograph.

Fast forward about 1/2 century. S&W devises the second iteration of the full moon clip, the star shape we are most familiar with. The factory has no intention of producing these. Instead, Ranch Products in Malinta Ohio is approached and asked to make the little clips. They agree. S&W supplies all the specs and drawings for the manufacture of the clips. Ranch Products is still making them, and to the original specifications.

Other companies make a similar shape but try to “improve” it. Some companies simply buy from Ranch Products, rebrand the clip and charge more for it. I use Ranch Products exclusively, probably have 4-500 and try to keep them all loaded.

If the clips is made to S&W specifications, it should not be tight.

See the above explanation.

Tools to load and unload the clips are easily bought or made. I modified a set of water pump pliers to squeeze two rounds at a time into the clips. The tube mentioned above to unload them works well. I have made dozens.

Full moon clips are the fastest reload available. They also keep your brass together. Can they get bent? Sure, I think I have had a dozen or so bent because a Range Officer at a match stepped on them. I know an arm on one snapped off and the clip was replaced by Ranch Products.

If you have any questions, ask them! Someone on this forum will have an answer.

Kevin