Welcome ! OAL is set by how

your bullet fits into

your barrel....

NOT the OAL listed in the loading manual.

► You did not tell us your gun, so no one here can suggest an OAL.

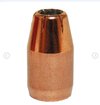

► The OAL in the manual is the OAL they used in

their gun. Their "handgun" looks like this....

• Hornady and Hodgdon are REPORTING the OAL they used during their testing. They are

not making a recommendation.

• You'll need to measure how that bullet interfaces with YOUR barrel and then make reasonable adjustments and plans based on your experience with the cartridge and pistol. Each bullet-to-barrel interplay is different/ unique/ individual.

• Understand that ALL auto pistol cartridges allow a RANGE of OAL to be used. There are PHYSICAL limits used by the shooting industry, and then typically further restricting those are the LOAD limits set by Your gun and Your load recipe.

The following cartoon shows/ explains this better....

► On the outside we have the SAAMI Physical limits for 9x19 Luger. Longer than ~1.169" won't fit inside the mag; shorter than 1.000" won't feed well.

► Typically, further restricting those are the additional limits of reality. You don't want to go shorter than the Reported OAL in the recipe, to prevent chamber pressure spikes. You do not want to go longer than what the barrel will accept, due to fears of creating a cartridge that has the physical ability to create an

Out Of Battery accident. Every bullet is different; every barrel is different. No one here can advise you on this number... you have to measure it for yourself.

► ► Between those 4 Limits is a "zone" or range of OALs that is safe to use. This part is the

Science of Reloading. Then, based on your past experience with your handgun (and the notes in your reloading notebook), within that range is an OAL that will allow your handgun to feed well and deliver the desired accuracy. This part is the

Art of Reloading. Welcome to Reloading !

Hope this helps.