The old true wadcutter brass was different, but new brass especially Starline is all the same.This is mostly true, although thickness varies.

At any rate, I do like the others, I have/do shoot .38 Spl loads, or even lighter, including WCs in the past, from .357 Mag brass.

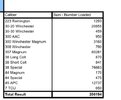

View attachment 1193775

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Wadcutters in 357 Mag Brass

- Thread starter Bill_in_TR

- Start date

I know Hodgdon lists magnum primers for all their .357 loads. That does not keep me from using standard primers with light loads if I feel they will work better. I have come to prefer to shoot 125 plated bullets instead of wad cutters. I am not able to capitalize on cutting edge accuracy anyway. On a good day I have done about 1 1/4" inch groups at 25 yards with the 125 plated bullets and a Red Dot sight, rested. But most days I can not shoot that well. But...that lets me know "It ain't the loads, stupid" when I do not group well.

I managed to squib one WC load in 357 brass.

I loaded some plated wadcutters in magnum brass with 38 data (+.2 grains) and used longer OAL.

First shot was around 450 fps, second shot stuck in the bore of my revolver.

My bad. Changed too many variables without work up.

I still like magnum brass and plated bullets, just need to compensate with a little more powder.

I loaded some plated wadcutters in magnum brass with 38 data (+.2 grains) and used longer OAL.

First shot was around 450 fps, second shot stuck in the bore of my revolver.

My bad. Changed too many variables without work up.

I still like magnum brass and plated bullets, just need to compensate with a little more powder.

Bill_in_TR

Member

The last time I loaded wadcutters quite a few years ago I seated them pretty close to flush with the neck of the case but that was in 38 brass. How do folks seat wadcutters in 357 brass?

I seat them flush or pretty close for HBWC. These new Berrys DEWC I’m using now are seated with about 0.105” out of the case, but that’s in a 38 Special. COAL is about 1.265” according to Lyman’s cast bullet data. If I loaded the Berrys into a 357 Mag case I’d probably seat them near flush.

nofendertom

Member

- Joined

- Sep 12, 2019

- Messages

- 1,019

When I shot HBWC in .38 or .357 brass I loaded them flush. With DEWC in .38 or .357 brass I load them in the crimp groove.

Now I only shoot 158gr LSWC.

Now I only shoot 158gr LSWC.

I believe you, but haven't had any issues with any of my range brass I've picked up over the years.The old true wadcutter brass was different, but new brass especially Starline is all the same.

Most of the cases in the last 25 years have been the same with a few exceptions, I am still using cases from the 1980's because loading just target rounds they almost last forever.I believe you, but haven't had any issues with any of my range brass I've picked up over the years.

I use the Star cases in my 357 rifles mostly.

GeoDudeFlorida

Member

- Joined

- Dec 1, 2020

- Messages

- 11,112

Depends on the bullet: I seat to the crimp groove if it has one or flush + a thumbnail if it doesn’t. I only seat below the edge if the case has a seating band in the correct position. Those are pretty rare but I have had a few.The last time I loaded wadcutters quite a few years ago I seated them pretty close to flush with the neck of the case but that was in 38 brass. How do folks seat wadcutters in 357 brass?

.38 Special

Member

- Joined

- Sep 15, 2006

- Messages

- 7,371

I am another who prefers to use .357 brass in .357 guns. My favorite .38 wadcutter load is 2.7 grains of Bullseye, and it can be duplicated in .357 brass with 3 or 3.1 grains.

I load plated DEWCs to 1.440”, quite long, no particular reason. Add powder!The last time I loaded wadcutters quite a few years ago I seated them pretty close to flush with the neck of the case but that was in 38 brass. How do folks seat wadcutters in 357 brass?

Swaged HBWCs to 1.320”, most load these flush.

Cast DEWCs seat to crimp groove length, 1.390” for Penn DEWCs.

I use a taper crimp for cases that are not trimmed to the same length and a roll crimp on trimmed cases.

I went back to just shooting SWC, RN and RF 158 grains because the full wadcutter didn't really give me any advantage for what I shoot.

Plus casting SWC, RN and RF is easier than casting HBWC's. DDWC are not to hard to cast, but for me they take more care to seat and crimp.

I went back to just shooting SWC, RN and RF 158 grains because the full wadcutter didn't really give me any advantage for what I shoot.

Plus casting SWC, RN and RF is easier than casting HBWC's. DDWC are not to hard to cast, but for me they take more care to seat and crimp.

MBC's, Hi-Tek wadcutters do work well and are the cost effective for store purchased bullets.I have a good supply of Berrys DEWC but may try some Acme or MBC wadcutters when I run out. I’ll have to try some of the Berrys in 357 cases.

Do tell. Where can this be found? Old Lyman manuals?The cast or cast/coated DEWCs with crimp grooves can be driven to some impressive velocities and are hell on vermin.

I have some old data from Lyman and RCBS that drives them over 1300 fps (lynotype).

nofendertom

Member

- Joined

- Sep 12, 2019

- Messages

- 1,019

My Lyman manual, 45th Edition shows a 141gr cast WC (#2 Alloy) being driven with max loads being driven between 1011fps and 1543fps.

Last edited:

I have always had better accuracy seating wadcutters long, with the crimp in a lube groove.

Regardless of whether I used 38 or 357 cases.

The bullet ends up in the throat of the cylinder...

I have posted this many times before and is probably in all the Similar Posts listed at the bottom of this page!

.

Edit: Another benefit of doing that is you can duplicate the case volume of a 357 in a 38 case by seating the bullet out.

Regardless of whether I used 38 or 357 cases.

The bullet ends up in the throat of the cylinder...

I have posted this many times before and is probably in all the Similar Posts listed at the bottom of this page!

.

Edit: Another benefit of doing that is you can duplicate the case volume of a 357 in a 38 case by seating the bullet out.

Last edited:

‘The complete reloading manual for the 357 magnum’ ~$10 from Midway. It’s a collection of data from bullet and powder manufacturers.Do tell. Where can this be found? Old Lyman manuals?

My copy is quite old, so I don’t know if current copies are the same.

bullseye308

Member

I’m still shooting a bunch of Sears, Western, & S&W 357 brass I acquired decades ago. 5.0 grains of Bullseye and a 158 cast and tumble lubed swc is what i shoot in 357.Most of the cases in the last 25 years have been the same with a few exceptions, I am still using cases from the 1980's because loading just target rounds they almost last forever.

I use the Star cases in my 357 rifles mostly.

I’d not really given much thought to a 148 wadcutter in a 357 case but now I’m thinking it sounds like another interesting option to try. Once it warms up and is dry I’ll load some up and see.

Bill_in_TR

Member

MBC's, Hi-Tek wadcutters do work well and are the cost effective for store purchased bullets.

Hmmmmm.I just recently got in some coated round nose in 9mm and 45 from MBC. I haven't loaded any yet because life is getting in the way recently. But they look really nicely made. I may have to order some of their waddutters. The only question is they are cast softer than their stuff intended for higher velocities. Not that I really want to push wadcutters really fast but you never know when the urge might hit me.

Similar threads

- Replies

- 7

- Views

- 3K

- Replies

- 23

- Views

- 789

- Replies

- 38

- Views

- 3K

- Replies

- 6

- Views

- 5K