before you start assuming I think it's got anything to do with lawyers.

"Get some old books and compare bullet-to-bullet, apples-for-apples, and leave out the prejudices."

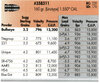

Lyman Ideal No.40, Lyman bullet #358311/358432 (20:1 Alloy)

Bullseye - Start: 2.7 Max: 3.2

Unique - Start: 4.5 Max: 5.2

Lyman No.44, Lyman bullet #358311 (#2 Alloy)

Bullseye - Start: 2.0 Max: 3.5

Unique - Start: 3.5 Max: 5.4

Lyman No.48, Lyman bullet #358311 (Linotype)

Bullseye - Start: 3.2 Max: 4.1

Unique - Start: 4.2 Max: 5.3

I don't know what you're seeing in this timeline of data that tells you "maximum pressure" is being avoided or something has changed drastically over time. I don't see anything being "watered down" and I'm looking for it. I see progressively

higher charges with progressively

harder alloys. From Lyman No.40 to Lyman No.48, nothing has been watered down for any reason. What's so hard to understand about that?

Bottom line and then you can have the last word because this is sounding more like "The Religion of Ka-Boom" than the arts and crafts of handloading. If all a handloader cares about is max! Max! MAX!!!! then they really have no business behind the trigger. That's my opinion. Disagree if you like - or just go blow up a few guns like Elmer did - but I'm entitled to my opinion and in my opinion unless the SAAMI/CIP MAX!!!!! load is also the most accurate, easiest to manage, and overall useful load, then it's a waste of time, money and components. You're welcome to blow up all of your guns you want but I'd really prefer the manuals stick what won't blow up my gun, or anybody else's.