Driftwood have you tried any of the Slim Pony bullets that the folks in N. H. are casting?

Funny you should ask. Slim Pony bullets are made by two Cowboy shooters whose aliases (alii?) are Sixgun Swanzey Slim and Iron Pony. I don't see Sixgun very often, but Iron Pony is a very good friend, we have been shooting together for many years. Although I usually cast my own bullets, sometimes I get a little bit lazy and call up Iron Pony and ask him to cast me up 500 or so. He sends them to me unsized and unlubed and I lube/size them myself to save a few dollars. We both use the Big Lube molds sold by Dick Dastardly at Big Lube.com.

http://www.biglube.com/

As a matter of fact, just last week I finished lube sizing 500 of Slim Pony's 44 caliber bullets. Here is a plug for Slim Pony's website, incase anybody wants to try them.

http://www.shootingbums.org/slim-pony/index.htm

If you look at their products you will see the 44 caliber bullet I am talking about.

DMH:

Are you sure you didn't sneak over to my house and steal my old Marlin? Yours looks just like mine. Although mine was also made in 1895 and the rifling grooves are .427. I have no idea why yours is so different.

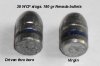

It sounds like you have a good handle on slugging a barrel, a .451 ball should work fine for slugging a 44-40 barrel. Just be sure that when you look at the high spots on the ball, you see drag marks running in the direction the slug was pushed through the bore. This photo shows some bullets I commonly slug 45 caliber bores with. The arrow on the center slug is pointing to the drag marks I'm talking about. Drag marks show the slug completely filled the groove. Without drag marks, the lead may not have completely filled the groove and any measurement taken may not be a true indication of the depth of the grooves.

It sounds like you have been more thorough than I usually am when I slug a barrel. I usually just run the slug from the muzzle to the breech. With some guns, Winchesters and most revolvers, it is impossible to slug the barrel from the chamber to the muzzle. With your Marlin by dismantling it you have a straight shot at the chamber. You can't do that with a Winchester or a revolver.

Anyhoo, when I slugged my old Marlin the slug ran all the way from the muzzle most of the way to the chamber with the same amount of resistance. As you obviously realize, that is a good indicator that the bore is the same diameter all the way. Then a few inches from the chamber it got very easy to push, with almost no resistance. That is fairly common with old rifles that have seen a lot of Black Powder shot through them without always having the best cleanup possible. It means the bore is eroded a bit near the chamber. Usually not a huge consideration, I have run into it a few times and the guns in question have shot fine.

Regarding pitted old bores, I read a long time ago that it was best to shoot Black Powder through a new, unpitted bore. The thousands of tiny pits tend to hold the fouling in and require much more elbow grease to get all the fouling out. While this is basically true, I no longer worry about cleaning out old pitted bores as much as I used to. It turns out, even if you don't get every last spec of fouling out of the bore, and there is still a little bit lurking down in the pits, as long as you give the bore a good coating of oil, I always use Ballistol, whatever fouling remains in the pits is rendered harmless and does not cause any further corrosion. It turns out that if you saturate Black Powder fouling with oil, it can no longer absorb any moisture from the air. It is like a sponge that is already saturated with water, it cannot absorb any more. Since the fouling cannot absorb any more water, it does not cause any more corrosion down in the pits. I have one old S&W top break 44 with a bore that looks like a minefield it is so pitted. But the rifling is still strong, and it shoots great.

The dimensions on your Uberti 1866 jibe with most of what I have been hearing about recent Uberti 44-40 rifles. Most of them slug at .429. My Henry, which I bought about 5 years ago, slugs at .429, although my 1873, which was made in the 1980s slugs at .427. To tell you the truth, when I slug a barrel, I never pay any attention at all to the bore diameter. I only care about the rifling groove diameter.

Try those soft .430 bullets and I bet everything will be fine.