Jonny2guns

Member

- Joined

- Nov 28, 2020

- Messages

- 677

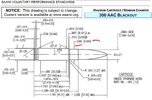

So I am trying to load some subsonic rounds for my 300BO, but I've tried a couple different bullets and when seated to listed COAL, the rounds will not plunk test in my gun. Even tried seating them a lot deeper and the bullet hits the rifling before the bolt closes.

I don't remember the manufacturer of the upper but I got it from Midway. It's stamped 300BO 1:8

I don't remember the manufacturer of the upper but I got it from Midway. It's stamped 300BO 1:8