Edit Alert

Sorry guys...I put in the wrong drill rod size in my response to Tarpley. See the edited text.

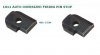

As an alternate method the EGW stop can be beveled lightly to just break the corner and stoned to blend it into a more rounded shape. I prefer the full radius, but either will work.

The egg asked:

The only way to know is to run double blind tests.

Can Tuner or some other advocate do this? I am sure you know how.

*****************

Sure. Just cut one with the radius and use a standard stop in the same pistol. Yes...I've done it. Yes...there is a difference in felt recoil and muzzle flip. Another test is to use a shock buff and see how much longer they last

with the small-radius stop. Again, the difference is the result of the mainspring absorbing a little of the slide's energy and delaying it for just a

fraction of a nanosecond before the slide gets moving. Thus it "bleeds off" a little of the recoil energy in the beginning of the cycle, rather than depending on the recoil spring alone to handle it. Simple physics. If the mechanical advantage used to compress the mainspring is reduced, the slide has to work harder to overcome the spring's resistance to compression, and that takes time. Time to let the chamber pressure drop...Time to get the slide moving at full speed...Time to cock the hammer against the mainspring. The delay is

very short, but things happen fast inside the chamber and barrel. Once the hammer is cocked, the influence of the stop is over...but its mission has been accomplished and the slide moves a little slower as a result. Lower slide speed means less shock when it hits the frame. Less shock means less felt recoil.

Luck!

Tuner