BigMacMI

Member

- Joined

- Nov 17, 2016

- Messages

- 127

My problem is this: Cast boolits sized to not lead my barrel will not chamber properly. They are not hitting the lands, but rather, the boolit diameter (.3585) is just a bit too fat to chamber in the throat. If i size them to .356, I can load them plenty long for my needs, but they are not large enough.

I spoke with Brownells today, but was having a difficult time explaining exactly what I needed... I had initially thought i needed a finisher style throater: https://www.brownells.com/gunsmith-...--sku184053380-17633-11648.aspx?sku=184053380

But he then pointed me to a different tool: https://www.brownells.com/gunsmith-...r-sku513051901-40866-19478.aspx?sku=513051901

It may be that I had my terminology wrong.

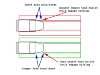

I need the 'free bore' area shown below a larger diameter... not necessarily longer. But if it must go longer to get wider, I am OK with that.

I am having an experienced machinist do the work for me. I just need to come up with the tools

I spoke with Brownells today, but was having a difficult time explaining exactly what I needed... I had initially thought i needed a finisher style throater: https://www.brownells.com/gunsmith-...--sku184053380-17633-11648.aspx?sku=184053380

But he then pointed me to a different tool: https://www.brownells.com/gunsmith-...r-sku513051901-40866-19478.aspx?sku=513051901

It may be that I had my terminology wrong.

I need the 'free bore' area shown below a larger diameter... not necessarily longer. But if it must go longer to get wider, I am OK with that.

I am having an experienced machinist do the work for me. I just need to come up with the tools