Whatever you end up using, just go very slowly and take off a little bit of material at a time. Unless you have some kind of deadline, removing too little is not a problem--you can just take off a bit more. Removing too much, on the other hand... Where people get in trouble is they get impatient and/or tired and start trying to speed things up, then they take off more than they intend, or the tool slips.

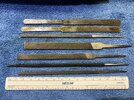

If you file, take a stroke or two, look at everything to see if the file is touching/cutting something you didn't mean it to, make sure the removal is going to be level with the original surface, then repeat. You'll learn as you go--just go slowly enough and check frequently enough that you have a chance to learn before something gets messed up.

If you get tired or start feeling the need to go fast, put it away and come back another time.

Leaving a radius (even a small one) in the corners will make it stronger and less likely to fail in the future.