JHTexas

Member

- Joined

- Dec 2, 2018

- Messages

- 131

RoundnessAcme bullet has been run through Lee .452” sizer to ensure size and shape (what term do I want here? Concentricity?)

RoundnessAcme bullet has been run through Lee .452” sizer to ensure size and shape (what term do I want here? Concentricity?)

I totally understand. Maybe not even the best suggestion, it's just what I did so my son didn't just grab a box of my loaded rounds and select the short throated 1911 or CZ, they typically have short throats.I have the tools (my grandfather was an instrument maker) but not the experience nor nerve.

Yeah as great as THR is it ain’t no FCD support groupA few years ago I acquired a nice used Tanfaglio Witness 45acp. When I tried loading .452" plated bullets in it I ran into all sorts of problems. Kept having feeding, chambering issues. So a moderator on the CZ forum suggested a Lee FCD and it all went away. Faced a lot of grief for posting that back then and was unconditionally told by a number of members here and elsewhere there was a problem with my reloading and the FCD was a "Band-Aide" fix. Well as it turned out there was/is nothing wrong with the reloaded bullets. They all performed perfectly in 3 other pistols. Then I tried with some cast lead bullets also sized to .452" with the same results. Then purchased a sizing die for .451" and magically all the problems disappeared and didn't need the FCD any longer.

So if I understand you correctly the Lee FCD was sizing down the O.D. of your loaded rounds by .001" or more and by using the .451 diameter bullets you no longer needed the Lee FCD to reduce the diameter of the loaded rounds?A few years ago I acquired a nice used Tanfaglio Witness 45acp. When I tried loading .452" plated bullets in it I ran into all sorts of problems. Kept having feeding, chambering issues. So a moderator on the CZ forum suggested a Lee FCD and it all went away. Faced a lot of grief for posting that back then and was unconditionally told by a number of members here and elsewhere there was a problem with my reloading and the FCD was a "Band-Aide" fix. Well as it turned out there was/is nothing wrong with the reloaded bullets. They all performed perfectly in 3 other pistols. Then I tried with some cast lead bullets also sized to .452" with the same results. Then purchased a sizing die for .451" and magically all the problems disappeared and didn't need the FCD any longer.

I love and use my 38/357 fcd like a boss. I must have a big ring in mine because it almost never does any sizing, but just crimps like I need it to. If I over flare I will get an initial bump but I know exactly what that is and why. In the described senerio the bullet is swaged either way and is needed. My only thought might be the loss of some neck tension.Yeah as great as THR is it ain’t no FCD support group

My journey is similar to yours (hello I’m CQB and I used an FCD). Hope tomorrow changes everything.

I no longer use it but understand it’s benefits (there I said it).I love and use my 38/357 fcd like a boss. I must have a big ring in mine because it almost never does any sizing, but just crimps like I need it to. If I over flare I will get an initial bump but I know exactly what that is and why. In the described senerio the bullet is swaged either way and is needed. My only thought might be the loss of some neck tension.

Only explanation I have. I doubt it was even actually .001".. I also found that by using thin walled brass made a difference. Still shooting that gun exactly how it was and it is very accurate.So if I understand you correctly the Lee FCD was sizing down the O.D. of your loaded rounds by .001" or more and by using the .451 diameter bullets you no longer needed the Lee FCD to reduce the diameter of the loaded rounds?

I hear ya, All my other pistol die sets are just 3 dies. The same way I learned to back in 1980.I no longer use it but understand it’s benefits (there I said it).

I haven't read any Pros and Cons on the FCD. Is there a love hate relationship going on there?I no longer use it but understand it’s benefits (there I said it).

Yes but shhhhhhhI haven't read any Pros and Cons on the FCD. Is there a love hate relationship going on there?

None for me, I have a tooth ache.I’m starting the popcorn…

Excellent summary. It still annoys me that the two reloading books I have do not mention the plunk test. It seems the plunk test should be one of the basic lessons in a reloading book.My take away.

Gauges are not barrels.

Gauges are like a chamber with a short smoothbore barrel and no rifling (but with a stop for maximum overall length).

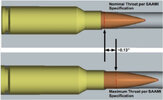

Pistol barrels have Rifling and Leade (Throat) between the barrel chamber and rifling.

Leade (throat) may vary between barrel manufacturers

A loaded round may pass the gauge test and fail the barrel "plunk" test because of bullet nose shape (ogive).

Confirms my practice of "plunk" testing my all reloads in the barrel of my pistol after loading.

saami.org

saami.org

I load for 7 9mm in my family and 3 .380. Before I started using Wilson gages, I had problems - nearly the direct reverse of CQB. I am now scratching both ends, and I have a headache.

Thanks I appreciate you trying to help. All y’all for that matter.What you are seeing is why you need to set your dies for “plunk”, then use your case gauge (no rifling to contact at any length). Chamber reamers are not only different (angles and tapers into the rifling that is cut into the barrel) but even ones ground to the same specifications wear And change what they cut. Why there are tolerances vs just a single dimension it must be. In other words, there is a range of OK And your load is right in that range.

When that changes, so does allowable bullet seating depth.

View attachment 1170543

You don’t need any special dies, just seat the bullets a tad lower if you want them to all plunk right. Also note the barrel with the shortest lead as one to use upon setup, in the future. If you use the one from the gun that will run anything, the finicky ones will still choke.

Sounds so intuitive & plain language. I like it so it must be wrongRoundness

The problem appears to be a bullet problem, specifically the Acme 230RN .452”. And not just one lot. I hope to find out today resizing some down to .451”….

OkayI suppose the reason why I am focused where I am stems from back around 2002 when David (Precision bullets) stopped casting his bullets and started swaging them. They were still a 230 grain round nose but they have a little flat spot right on the tip. Many in our club that shot them had problems because they loaded them to the same OAL as the cast ones and the ogive of the bullet contacted rifling. The solution was to seat the bullet deeper, so if it didn’t actually have that flat spot it would be the same OAL.

View attachment 1170702

Here is the funny part. All of them that had the problem, created it. Those that just opened the box started loading them with the same everything else they used for his cast bullets were fine.

If you were one whom paid attention to details, you would have noticed the rounds came out “too short”. Everyone that adjust their dies to get the correct OAL, had the bullets contacting rifling afterwards.

View attachment 1170703

Vs your other 230’s.

View attachment 1170704

But that’s not the whole picture. Sometimes, as with rifles an ogive measurement is worth doing (the closer to bullet diameter the better because that’s what’s going to be contacting the rifling).

For this example I just removed the seating stem but we can see that as far as the firearm would be concerned, the two are the same, despite different OAL’s. Why people who did nothing were fine.

View attachment 1170705

View attachment 1170706

Fortunately I’m dealing with little blobs of lead and not gold. So I can afford to just let it go but somehow just can’t.

Did the round fully seat after you did this?Okay

View attachment 1170712

Well I knew your comments were based in sound analysis.

Fortunately I’m dealing with little blobs of lead and not gold. So I can afford to just let it go but somehow just can’t.