SSN Vet

Member

Most likely:

1.) someone bent the sear spring to lighten the trigger pull and now it won't reliably engage the sear nose into the hammer hooks.

2.) someone filed the hammer hooks too low and now they won't reliably engage the sear.

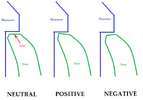

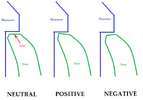

3.) someone filed/stoned the sear nose and created a negative angle that will not reliably engage the sear.

4.) all of the above.

1.) someone bent the sear spring to lighten the trigger pull and now it won't reliably engage the sear nose into the hammer hooks.

2.) someone filed the hammer hooks too low and now they won't reliably engage the sear.

3.) someone filed/stoned the sear nose and created a negative angle that will not reliably engage the sear.

4.) all of the above.