So, Steyr walked away from you. Told you to go piss up a rope? Not a very professional organization which stands behind its product.

This ought to be of interest to those who wonder what firing pin offset is acceptable in a small arm:

Report No. R-462 Primer Sensitivity vs. Firing Pin eccentricity

Frankford Arsenal Dec 1943

Object: To determine the effect of firing pin eccentricity on the sensitivity of small arms primers

Summary: Retaining firing pin plates were constructed for the drop test machine that have blows eccentric by .00”, .02” and 0.04”. Drop tests were made on cal.30, .20 carbin, cal 0.45, and cal .50 primed cases (in cases) with sharp anvils, and on cal .30 primers (H-4 in cses) with flat cups.

Very little, if any, changes in sensitivity occurs with blows of 0.02” eccentricity; large differences occur with blows of 0.04”.

“H bar” H̅ is the mean critical firing height. (approximately the 50% ignition point)

From

Percussion Primers, Design Requirements , McDonnell Douglas 1970:

“Primer manufacturers in their data sheets customarily provide the 100% “all fire” level of their products. This is essentially the same as the mean firing height plus five standard deviations.”

The 1943 report shows for the Cal 0.45 H̅ with a four ounce weight is 3.70” for 0.0” eccentricity, 3.70” for 0.02” eccentricity, and 5.11” for 0.04” eccentricity.

George Frost, in his book

Making Ammunition, shows data that the further the firing pin hits, the more energy it takes to ignite the primer. At some level of firing pin offset, the primer is not going to go bang. Maybe a torch will make it ignite, none of my weapons has that option.

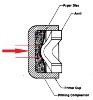

Contrary to the conventional wisdom held by many, the further from the center of the primer, and the tip of the anvil, the more likely is the probability of a misfire. Maybe this cross section of primer construction will help in understanding this:

View attachment 1083309

The further from the tip of the anvil, the less reliable ignition will be.

I am of the opinion that manufacturer’s ought to design their weapons with sufficient ignition system energy to ignite cartridges under all environmental conditions, and they ought to manufacture the ignition system so the firing pin hits the primer dead center. Surprisingly, some disagree with one or other of these statements.

In my own experience, I found that a shallow shoulder, insufficient firing pin protrusion, and off center firing pin hits do lead to misfires. I fixed my misfire problems with this Dumoulin M98 action that I had built into a 35 Whelen rifle.

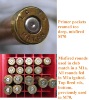

View attachment 1083310

View attachment 1083311

View attachment 1083312

The rifle misfired with cases having zero cartridge headspace clearance, and Federal primers. I rummaged around my box of Mauser parts, found a military firing pin with more firing pin protrusion, and that fixed the problem.

This Ruger was beyond anything I could do.

View attachment 1083313

View attachment 1083314

The firing pin offset was very obvious, gross in my opinion. Sorry all the cases have been reused and no pictures of the firing pin offset is available. To back track a bit, the 35 Whelen is the only cartridge which I don’t set the shoulder back 0.003” on resizing. I have found my ignition reliability goes up when the sized cartridge is exactly chamber length, or a tiny crush fit. Based on my observations, the shallow shoulder of the 35 Whelen does not provide best rigidity when hit by a firing pin.

View attachment 1083315

That case must be deforming, resizing, something like that, when the primer is hit. I think that is the reason for sharp shouldered versions of the 35 Whelen, such as the 35 Brown Whelen cartridge.

https://www.cartridgecollector.net/35-brown-whelen

I also made sure not to ream the primer pockets excessively deep (you could bury Jimmy Hoffa in some of my over reamed pockets, and those will also misfire.

View attachment 1083316

I used the most sensitive primers on the market: Federal standard rifle primers. And then, I purchased a Wolf extra power mainspring, installed that in my Ruger #1, and the rifle still misfired. So, I had reached the limits of what I could do, and sent the rifle to Ruger. I got to talk a very knowledgeable technician, and was very pleased to find that Ruger really is a professional organization!. The technician/gunsmith had measured the firing pin offset, measured the firing pin ignition power, fired the rifle with their ammunition, and it was within their specs! EEK!

These are my phone notes:

Telephone Notes Ruger Customer Service, Ruger #1 in 35 Whelen

Headspace within Go and No Go

Ruger firing pin offset criteria:

Reject at 40 thousandths (0.04 inches)

My rifle: 25-30 thousandths (0.025-0.030 inches)

Ruger sometimes rebuilds at 35 thousandths.

SAAMI copper indent standard 17 thousandths (Note: copper crush depth a measure of firing pin energy) My rifle: 23 thousandths.

Note: I installed a Wolff extra power mainspring and did not remove it when sending the rifle to Ruger.

A Ruger M77 will give 19-20 thousandths copper crush, so my #1 has more powerful ignition

A source of unreliability is the shallow shoulder of the 35 Whelen, they has same misfire issues with 7.62 X 38 ammunition, misfires due to shallow cartridge shoulder.

According to their inspection criteria, the rifle was within spec and the technician was not authorized to do anything. Buggers! But, I told the technician what I had done (with the exception of mentioning the Wolf extra power mainspring, as I had forgotten I had installed it!) and I said, the rifle will continue to misfire because I had run out of options. I also offered the opinion, the offset reject criteria was too wide for the 35 Whelen cartridge. Not that he, or I could do anything about change the written procedures.

Well, he did something. I think he installed a longer link with lifted the breech block up, and centered the firing pin hit. But let's just keep this between us girls, as Corporate may punish the man for exceeding his authority. So the rifle is now reliable with ammunition that misfired previously! What a great guy to fix my problem.

But, it is my opinion that firing pin offset ought to be zero on a new rifle. As I have discussed, the more firing pin offset, the more energy it takes to ignite a primer, and at some level of offset, the gun will no go bang. Given cold weather, weak mainsprings, insensitive primers, the chances of a mis fire go up.

Steyr ought to have offered to measure the offset with your rifle, and the firing pin strike energy. And in my exalted opinion, in this day and time of CNC machining, no rifle should come off the production line with off center firing pin hits. For a reality check, my opinion and $1.50 will buy a cup of coffee. Baying at the moon has more affect on the earth's orbit than any opinion of mine has on Corporate Quality Control!

So, if Steyr has told you to piss up a rope, maybe they will act differently if the weapon misfires. Maybe they will just send you another rope.