I have built several garage and portable reloading benches for myself and other reloaders over the years.

Garage benches were usually built 2'W x 5'L (or longer) using 4x4s as corner posts and 2x4s as frame rails. Portable benches with casters were built with 2x4s and at 2'W x 2'L so they will roll through any inside doorway (common door frame opening is 27.5" with the door open) and into the closet for storage (my reloading room's walk-in closet door frame opening is 26" with the door open). Height of the bench is matched to the user's height for ergonomics. I use casters from Harbor Freight furniture moving dolly as they are rated for heavy weight and they roll easy on the carpet/don't mar the hardwood floor ($8-$10 on sale = $2-$2.50 per caster). The 2x4s are fastened with 8d/10d nails and 4" drywall screws. Presses are bolted with nylon locking nuts. Bottom shelf has another 2x4 brace in the middle so you can put as many boxes of bullets as you want there (I have put up to 40K bullets on the bottom shelf with no show of deflection and the bench still rolled easily - it is rated for much more weight).

I have used 2x6 as bench top material, but it split/cracked/chipped as the wood dried within a year. I usually use plywood or OSB screwed to the top of the 2x4 frame rails with another 2x4 added for strength/stiffness. I have noticed that OSB actually provides greater degree of stiffness and is cheaper than plywood (check the discard bin at HomeDepot/Lowes and you may get lucky too). I even thought about using two layers of plywood/OSB, but with the 2x4 frame rails and single layer plywood/OSB, the bench top does not flex and the stiffness increases for the smaller portable bench.

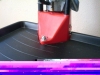

For ease of cleaning, I wrap the bench top with heavy vinyl sheet from the craft section at Walmart (usually $2-$3 worth) and staple to the inside of the 2x4 frame rails. To catch any spills and keep loose components from rolling off the bench top (like live primer into the carpet) I used to add a strip of wood at the edge of the bench top under the vinyl, but now use plastic trays cut around the press (I buy these at the dollar store - they are called All-Purpose Tray and used for muddy boots by the door).

This small portable reloading bench can be used just about anywhere in the house. I roll it into the living room to deprime/size while watching TV (patio for watching the sunset with wife), remove the plastic trays to sort range brass (I have a dedicated sorting deep pan with multiple boxes for different caliber, and roll it into the reloading room for focused/concentrated reloading.

Station one die hole is empty because the depriming/sizing die is on the RCBS RS5 single stage for separate depriming/sizing.