Mauser fan

Member

I bought a complete bolt this past weekend for one of my type 99 Arisaka receivers and it fits well. Then I re-installed the original barrel back onto the receiver and checked the headspace and it is .051 inches over the max.I also slugged the barrel and it is a rock solid .312 with sharp rifling and the barrel is Crome lined. It would be a shame to scrap it.

I have a set of RCBS 7.7 Jap dies and have made 20 cases from 30-06 cases all chamber just fine just too much headspace. So I have barrel issue. I know that the 7.7 chambering was designed to be sloppy and be fired with a relatively dirty chamber. But .051 over?

The trim to length for the 7.7 case is 2.270 inches, max case length is 2.280 inches. The chamber measurement is 2.331 inches which is .051 over the max. A 30-06 case has a maximum overall length of 2.494 inches.

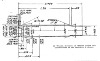

So as far as I can tell I have 2 options. Set the barrel back or re-chamber it to a different cartridge. Setting it back has a very unique set of challenges mainly dealing with the channel cut for the extractor. Not impossible but a great deal more work to do so.

I have read that 7.7 Arisaka's were re-chambered for use with 30-06 in the original barrels during the Korean war by the US govt. for the South Korean Army. It seems to be a simple straight forward task to do so.All that I would need to get is the reamers a rougher and finisher and I would have to change the de-capping pin in a sizing 30-06 die from a .308 to a .312 de-capping pin.

Has anyone else done this?

I have a set of RCBS 7.7 Jap dies and have made 20 cases from 30-06 cases all chamber just fine just too much headspace. So I have barrel issue. I know that the 7.7 chambering was designed to be sloppy and be fired with a relatively dirty chamber. But .051 over?

The trim to length for the 7.7 case is 2.270 inches, max case length is 2.280 inches. The chamber measurement is 2.331 inches which is .051 over the max. A 30-06 case has a maximum overall length of 2.494 inches.

So as far as I can tell I have 2 options. Set the barrel back or re-chamber it to a different cartridge. Setting it back has a very unique set of challenges mainly dealing with the channel cut for the extractor. Not impossible but a great deal more work to do so.

I have read that 7.7 Arisaka's were re-chambered for use with 30-06 in the original barrels during the Korean war by the US govt. for the South Korean Army. It seems to be a simple straight forward task to do so.All that I would need to get is the reamers a rougher and finisher and I would have to change the de-capping pin in a sizing 30-06 die from a .308 to a .312 de-capping pin.

Has anyone else done this?