I use both Brownells' Oxpho-Blue & Formula 44-40. I find that the metal prep is the key to a satisfactory result, whether it be a single small part or screw, or the entire firearm. I have observed the smoother the metal finish the better the take of the cold blue. I like to use a heat gun, really just warm the object up to hot touch, and apply with oil-free #3 / 4 OOO steel wool, using small wads of fresh steel wool for each application, linear in direction on receivers / barrels and long parts. Then apply something like Barricade spray. Done.

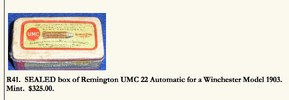

Here's a family hand-me-down disaster Winchester 1903 .22 Automatic that looked like a sea anchor with baling wire to hold the forend to the barrel and a fractured buttstock waist. Found some fancy wood for stock fitting and elbow grease. Used Oxpho-Blue. Runs like a sewing machine. I authored a technical Manual on the rifle.

View attachment 1192030View attachment 1192031View attachment 1192032View attachment 1192033View attachment 1192034View attachment 1192035View attachment 1192036View attachment 1192037View attachment 1192038View attachment 1192039