Guys, using a standard lee sizing die. All rounds chamber in my rock river 10 and work as they should. They fit case gauge.

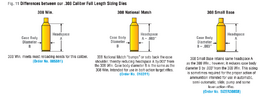

Will not fully chamber in my new m1a, about 1/8" from fully chambering. The base of a factory round a bit above rim is .462 and my sized brass using lee dies is .467. A factory new round chambers just fine as the .005" difference is enough i guess.

Looking here rc said sb dies shouldn't be needed.

Any advice. Thx in advance.

Will not fully chamber in my new m1a, about 1/8" from fully chambering. The base of a factory round a bit above rim is .462 and my sized brass using lee dies is .467. A factory new round chambers just fine as the .005" difference is enough i guess.

Looking here rc said sb dies shouldn't be needed.

Any advice. Thx in advance.