teerex.otw

Member

- Joined

- Jan 17, 2023

- Messages

- 256

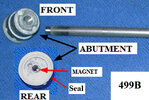

Is the diameter the same? I may slice and glue the difference of the original rubber abutment seal behind the plastic seal of the 38B my original seal is 23.3mm in diameter and 6.6mm in width

Terry shares some details of that trigger on page 71of this thread.Thank you both for the replies. I’m not really interested in drilling any additional holes in my gun at this time. I really like the looks of that metal trigger unit that is basically a replication of the factory plastic trigger. Is there a write up for that somewhere or does he sell them?

I'm using the match grade Daisy BBs. Don't have a chronograph but there's a very audible difference when they hit,compared to pre-Red Ryder spring.

From what I’ve seen, the people who ask that question, or roll their eyes, or some other negative reaction are (probably) the ones who didn’t have bb guns as a kid.Seems I’ve been following this thread for years…when questioned , “Why you messing with BB guns at your age?”

My philosophical brain hemisphere went into hyperdrive….

What American male child from sea to shining sea did not have some version of a BB gun as a kid?…( it’s rhetorical )

Childhood BB gun ownership is a major component to adult male mental health….BB gun ownership teaches the important life lessons skipped over by formal education….life and death, the roots of morality, the consequences of stupidity, Zen discipline, responsibility, loyalty, honesty and integrity….Soccer balls are cool but BB guns build character.

“Daisy RR facit virum”…..”The BB gun makes the man”.

The 499b abutment has different threads (5/16-24, if I remember correctly) than the screw-in shot tubes (7/16-14)Did some more searching. Wasn't able to find answers to my previous questions. Think I figured out what was needed for what I want to achieve.

Earlier Daisy's have an abutment that is held in with pressed tabs.

https://www.youtube.com/watch?v=eFotG8mBc_Q&ab_channel=RestOModDaisy

That part won't be hard to make since I have a lathe. I'll have to do some reverse engineering to figure out the dimensions. Then drill the receiver and hold it in place with a few spot welds.

It is the same diameter as the R.R.Well, that might rule out trying to use the 499 abutment. Haven't been able to find if it even fits a Red Rider. Drilling and tapping for the correct size is doable, but doesn't matter if it can't fit.

Looks like making my own is how I'm going to have to proceed. Would've liked a drop in solution. Got plenty of scrap steel and a lathe so making one isn't going to be too hard.

This is going to be an upgrade. No need for it to be removable.

I'm new on this forum and have not figure how to aks a question.Great info here!

Sounds like drilling and tapping a 499B abutment will get you where you want to go. The 499B abutment seal is different than the one used on the 1938B shot tube assembly. One member "Old George" out in CA (hey George!) did one of these and posted about it here, I believe. Or maybe he posted about it on Daisy Talk? Anyway, he used both the 499B seal and a 7/8" rubber abutment seal like used in a model 102 and others. The reason for the rubber seal is to get a good seal on the air tube's OD, because the 499B abutment has no provision to seal an air tube since the 499B has no air tube to seal in the first place.

View attachment 1191734

View attachment 1191735

Thanks for the help.The plastic loading door does have to be removed. There is only about a 3/8” hole through the middle of it for the shot tube to pass through, so it would be in the way of the feeder tube.

There are a couple of ways to cover the port. The easiest is to take a piece of thin sheet metal about

1-1/2” x 2-1/2” and wrap it around a socket (or something about the same diameter as the barrel shroud) insert and glue it in place. E-6000 works well for this. Just make sure you put the open part of this sleeve at the top so it doesn’t interfere with the tube, and deep enough to clear the front sight. You’ll still have the square port showing, but at least it will be covered to keep “stuff” out.

The other way is much more difficult, I’ve done it a couple of times, and it is a pain.

Wrap a short piece of 3/4” dowel with strips cut from an aluminum can until you get a good slip fit in the shroud, then solder in a piece the same size as the window over this (solder won’t stick to the aluminum, just to the steel around the edges). I cut my filler plugs out of a wrecked Ryder shroud, and did have to do a little “bodywork” to even things up. I also glued in a sleeve (as above) for added strength, and repainted it.

They turned out ok, but I’m not looking forward to doing another.View attachment 1191811