There's the million dollar question. I will take a crack, even though no one else on the planet will agree.

Why must the springs be so heavy. And have we answered the question about why guns shooting rounds like the .460 Rowland require MUCH heavier recoil springs?

Why must the springs be so heavy?

They don't have to be heavy. Do you know how to tell when to change the recoil spring in a Glock 17? When you point the gun up and let the slide return to battery, slowly, and it doesn't close all the way! That's not very heavy.

In a .460 Rowland, you are loading to higher muzzle velocities than the gun was designed. You can look at it many different ways, but the end result is the slide will recoil at a faster speed and chamber pressures will be higher.

Slide/frame battering: When the faster moving slide reaches the end of travel, it will hit harder than the gun was designed. There can be some stress damage or peening.

Extraction: When the case is extracted, the slide will be pulling the case out at a slightly earlier point in time, with a slightly higher residual pressure, and it will rip the case out at a slightly greater slide/frame speed. This puts more stress on the extractor and can cause failures to extract, broken extractors, and even case rims being ripped through.

Locking Lugs: the higher residual pressure and earlier (in time) unlocking have the effect of increasing wear on the locking lugs and the link. The barrel is being made to unlock faster and while under greater force between the lugs. Even if you think pressure is long gone the instant the bullet leaves the muzzle, the simple fact that the barrel essentially has a controlled collision with the frame in a short period of travel means the faster the slide travel, the greater the acceleration and stress. While the barrel is decelerating and dropping, the slide "wants" to keep moving; this increases the force between the locking lugs while the barrel is camming. Also, as barnbwt noted, the link(?)has a large role in arresting the barrel.

Recoil: with a stock spring, the slide will carry more speed/momentum when it hits end of travel, and this might make felt recoil worse.

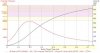

If you put in a heavier spring you can alleviate all of these problems, to some degree. But a heavier recoil spring slows the speed of the slide when it's near the end of travel relatively more than it can reduce the initial velocity of the slide, which is closer to where a lot of this bad stuff is happening. So there's a limit to the "spring fix". At some point, you will end up trading extraction problems for limpwrist malfunctions and stovepipes. You will also have a faster cyclic rate, and this can cause feed malfunctions where the mag spring can't push up the next cartridge in time for the slide to pick it up. Also, you can theoretically get some slide/frame battering from the return trip being too violent, as well as a more urgent problem of the firing pin lighting off the subsequent rounds by inertia. So you might have to beef up the firing pin spring, too.

If you wanted to take things up to an even higher level, you would need to increase the mass of the slide. (Of course, only if the chamber and locking lugs can handle that extra pressure). This is why no one makes a 9mm with the slide weight of an LCP. Even if there was someone who would find the recoil manageable, it could not be made to function reliably, let alone durably, with today's materials and methods.

Well, I have to take that back. If you increased the slide travel before the barrel unlocks, you could possibly get there. Picture a gun that is racked. Now, return the slide to battery. But where it would normally stop, it keeps going forward for another, say, half inch. With this setup, there is an increased delay before the barrel unlocks, and the recoil spring might also have a more efficient effect on reducing slide velocity by the time extraction takes place. The extra slide travel should potentially reduce the cyclic rate, as well, given a suitably lighter spring. But, then there's yet another problem with a light weight slide, even if it weren't for extraction and durability problems... Not only is there more felt recoil, but there's more recoil. The lighter the slide, relative to the bullet, the greater the share of the kinetic energy that it will receive. This has the effect of reducing muzzle velocity of the bullet and increasing recoil to the shooter. There is a very obvious diminishing return on reducing slide weight for caliber.

If you could increase the mass of the slide, it could fix all the aforementioned problems without so much of the drawbacks and limitations of using just a heavier spring. Also, with a 1911, you have the option to increase the weight of the mainspring, too. This will reduce the initial slide velocity by some degree without some of the negative consequences of increasing recoil spring weight.

And have we answered the question about why guns shooting rounds like the .460 Rowland require MUCH heavier recoil springs?

I believe the answer to this is no, because of the word "we." Agreement is not likely. This is just the way I see it.

Check out (b)Arfcom, sometime

Check out (b)Arfcom, sometime